Filter

La filtration des vins est une étape majeure dans la production de vin.

Ce sont les filtres qui permettent de mener à bien cette étape : le filtre presse, le filtre rotatif sous vide, le filtre à alluvionnage continu, le filtre à plaques, le filtre à modules lenticulaires, le filtre à cartouches, le filtre tangentiel et les média filtrants : les adjuvants de filtration, les plaques filtrantes et modules lenticulaires et les cartouches.

Ce sont les filtres qui permettent de mener à bien cette étape : le filtre presse, le filtre rotatif sous vide, le filtre à alluvionnage continu, le filtre à plaques, le filtre à modules lenticulaires, le filtre à cartouches, le filtre tangentiel et les média filtrants : les adjuvants de filtration, les plaques filtrantes et modules lenticulaires et les cartouches.

With very few exceptions, consumers want clear, brilliant wines that stay that way. This long-standing, strong and growing commercial demand means that visible or potentially visible particles must be eliminated, regardless of their usefulness, harmlessness or harmfulness. This is the role of filtration, clarification and wine stabilisation.

Plate filter

Plate filterTechnical presentation of wine filtration

Definitions

- To clarify is to obtain limpidity.

- Stabilising means maintaining clarity. Filtration, in conjunction with "good oenological practices" such as vinification, ageing, racking, fining, etc., contributes to current and future clarity.

- Filtering a must or wine means eliminating visible particles or particles that could become visible, by passing them through a permeable wall placed in a filter.

- Filtering means obtaining the desired clarity, at optimum cost, with maximum quality.

Note : racking and centrifuging eliminate particles by natural or multiplied gravity.

The different types of filter and their use

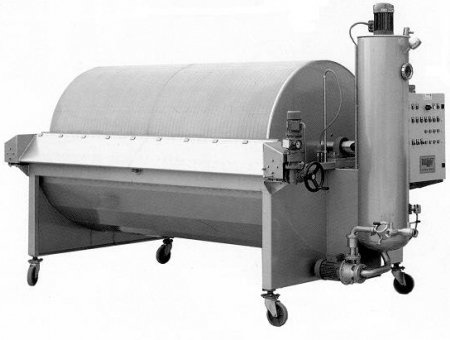

- Filter presses and rotary vacuum filters are used primarily for clarifying the most heavily contaminated products.

- Continuous-alluvium filters are highly adaptable for pre-filtering young wines and preparing wines before bottling.

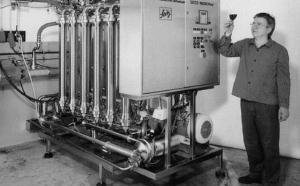

- Plate filters and lenticular filters are generally positioned before bottling; they are widely used in all production structures.

- Cartridge filters (with membranes) meet final filtration requirements, with or without germ reduction (sterilising filtration).

- Tangential filters are now widely used for wine preparation before bottling, filtration of young wines and microbiological stabilisation. New applications are being developed.

Which filter to choose?

In a winery, you may have to filter musts, wines, lees, etc. containing from 200-400 g/L to 1-10 mg/L of suspended solids, at flow rates ranging from a few litres to several hundred hL/h and costing from a few Euros to a few hundred Euros per litre. Clearly, the optimum choice is not always the same!This choice should only be made after careful consideration to avoid unsuitable results and/or economic setbacks.

The essential phases of good filtration

1 - Knowing the initial state of the must or wine

- Origin, various treatments, from harvest to current stage (must extraction, decanting, etc.)

- Current characteristics: cloudiness (turbidity), load

- Basic analyses: CO2, SO2, iron, copper, etc.

- Tasting

2 - Desired final state

- Fermentation, ageing, barrel filling, bottling, storage, etc.

- Maximum turbidity accepted

- Level of microbiological stability

3 - Filtration monitoring

- Pressure

- Flow

- Turbidity

- Incidents

4 - Checking filtration results, final characteristics

- Average turbidity

- Control analyses: CO2, SO2, yeast, bacteria, etc.

- Tasting

Note: in all cases, consult your oenologist. Keeping filtration records allows you to take all the parameters into account and accumulate instructive experience.

How do you judge filtration?

Turbidity

This is measured, in the cellar or in the laboratory, by the turbidity after filtration (the amount of cloudiness in the wine) expressed in N.T.U. (Nephelometric Turbididy Unit).| Turbidities usually recommended for musts and wines: | ||

|---|---|---|

| - Clarified must before fermentation : | 50-200 NTU | |

| - Slightly cloudy wine: | White | 4-5 NTU |

| Rosé | 5-6 NTU | |

| Red | 7-8 NTU | |

| - Bottled wine : | White | < 1 NTU |

| Rosé | < 1.5 NTU | |

| Red | < 2.0 NTU | |

Turbidity gives us information about the charge contained in the product (limpidity).

Under no circumstances does it reflect a state of filterability characterised by filtration capacity.

The viable germ content (yeast and/or live bacteria) is a technical and commercial constraint that is increasingly required. The current "commercial standard" is often less than 10 viable germs per litre (or bottle), even if the technical risks can be much higher.

Filtration capacity

This is the volume that can be filtered or the volume / cycle (for a given filter or per m2) before total clogging or, more often than not, before the flow rate falls below a pre-defined practical threshold.We often speak of 'cycle time' (in hours) and/or volumes filtered (in hectolitres).

The filtration speed (flow rate per filter or per m²) depends largely on the filter itself (useful filtering surface), the wine (more or less cloudy, clogging) and the way it is used. It is often dictated by the downstream organisation of the winery (e.g.: filler at the filter outlet at 1,000 bottles/hour).

Hygiene

Before and after each use, all filters must be cleaned, disinfected and rinsed with water and products suitable for oenology, in compliance with the recommendations of each manufacturer and the regulations. The usual method uses a complete filtration circuit with circulation of disinfectant liquid in an open or closed circuit, followed by vigorous rinsing. Hot water is very effective and widely used. The operation must be rigorous.Safety

Filters are subject to the general rules of the Machine Directive. The entire electrical supply must be protected in accordance with the rules in force, and each appliance must have CE certification on the equipment and the user manual.Discharges

Alluvial filters, filter presses and rotary vacuum filters retain very large quantities of inert filtering materials (filtration earth) and/or organic particles (sludge, yeast, bacteria, etc.), which are discharged into the sewage system, causing clogging of the pipes and a high chemical oxygen demand (COD).These discharges must be collected specifically, with a minimum moisture content, for controlled discharge into the natural environment (e.g. burial in agricultural land).

Direct discharge, with dilution, into direct drains is to be avoided.

Experiment

See the list of experimentsSee more - Impact of clarification processes on phytosanitary product residues: must, lees, bottoms, wines - 2019

- Innovative stabilisation techniques - 2019

- Impact of oenological processes on residues of plant protection products in wines - 2019

- Clarification and stability of wines for bottling: issues and prospects - 2018

- Variability of plate filtration - 2018

- Development of a new filterability test for wines - 2018

- Preparing wines for bottling: results on filtration - 2016

- Innovative processes for the microbiological stabilisation of wines - 2015

- On-property wine filtration techniques - 2015

- Study of new processes for clarifying lees and tank bottoms - 2014

- New processes for clarifying particle-laden liquids - 2013

- Improving the preparation of wines for bottling - 2013

- New techniques for the microbiological stabilisation of wines - 2012

- Clarification of musts from grape harvest heating processes - 2012

- Wine filtration: a literature review - 2011

- Crossflow microfiltration, applications in oenology - part 1 - 2010

- Crossflow microfiltration, applications in oenology - part 2 - 2010

- Crossflow microfiltration, applications in oenology - part 3 - 2010

- Clarification and stability of wines for bottling: issues and prospects - 2008

- Use of physical techniques during the mutage of sweet or syrupy white wines - 2008

- Impact of pulsed electric field treatment on the micorflora altering red wines - 2008

- Water notebooks: filters - 2007

- Crossflow filtration: materials and processes - 2005

- Filtration: pollution levels vary according to the type of filter - 2004

- Use of tangential microfiltration in mutage - 2004

- Bibliography on wine filtration - 2003