Temperature control equipment

Les installations de maîtrise de température, très évolutives, sont constituées de différents modules afin d'assurer d'une part une grande polyvalence des opérations thermiques et d'autre part d'assurer une meilleure surveillance des procédés en cours.

Le principe de fonctionnement consiste à mettre en place une production d'un fluide caloporteur (chaud ou froid) qui est ensuite distribué vers des organes d'échanges individuels. Chaque organe d'échange possède sa propre régulation manuelle ou automatique.

L'automatisme peut être assuré par des régulateurs de température, un automate ou un micro-ordinateur.

Le principe de fonctionnement consiste à mettre en place une production d'un fluide caloporteur (chaud ou froid) qui est ensuite distribué vers des organes d'échanges individuels. Chaque organe d'échange possède sa propre régulation manuelle ou automatique.

L'automatisme peut être assuré par des régulateurs de température, un automate ou un micro-ordinateur.

Temperature control equipment

For several years now, the constant drive to improve wine quality has led wineries to install temperature control equipment.Temperature control does not create new conditions for winemaking or maturing wines: it simply reproduces their best aspects.

From the grape to the glass, at every stage in its life, each wine must be prepared, vinified, stabilised and consumed at an optimum temperature with relatively small acceptable variations. At each stage of the winemaking process, this ideal temperature helps to improve the various aspects of the wine's quality.

- Development of grape and fermentation aromas.

- Clarification of musts and wines.

- Optimum development and inhibition of yeasts and bacteria.

- Extraction of skin compounds: tannins, anthocyanins, aromas.

- Optimisation of oxidation-reduction and esterification phenomena.

- Development of olfactory and gustatory characteristics

Outside winery

In most cases, good temperature control also makes it possible to optimise the use of vinification vats as well as wine ageing or bottle storage rooms.

Technical presentation

Each oenological operation must be carried out at a precise temperature in very variable climatic or practical conditions (premises).Equipment selection strategy

Defining the temperature control system best suited to a given production unit requires a whole series of technical, economic and practical parameters to be taken into account. To do this, a case-by-case study should be carried out with a professional, taking into account the following factors:- Overall heat balance for the farm (heat output and heat exchanger surface area)

- Choice of energy (electricity, gas, fuel oil)

- Choice of heat transfer fluid (water, brine)

- Level of control required (manual, semi-automatic, automatic)

- Choice of components based on reliability

- Quality of after-sales service

- Installation and running costs

Different types of temperature control equipment

- wine coolers and heaters

- heat treatment tanks

- external heat exchangers

- internal" and "belt" heat exchangers

- cooling tower

- the gas heater

- the immersion heater

- cO2 in the form of ice or snow

- vortex tubes

- cold or hot air generators

- other heat treatment systems

Which system should you choose? Carrying out a heat balance

Before choosing a heat treatment system, it is important to accurately assess the cooling and heating capacity requirements of the winery.The cellar heat balance is an assessment of the heating and cooling capacity, tank by tank, day by day, required to achieve the best thermal conditions chosen by the winemaker for each oenological operation.

The power to be installed can vary greatly from one winery to another, and depends on a wide range of factors:

- Type of grape: white, red or both

- Oenological operations to be carried out

- Daily input rate

- Vat materials and volumes

- Total volume vinified and volume per unit operation

- Duration of each operation and daily use of machinery

- Ambient temperatures (hot or cold years) or desired temperatures.

Find out more about the " Heat balance " module.

Following several years of observations, measurements and practical studies, we can propose a general method that can be adapted to each case. The questions that need to be answered are those that perfectly define the problems to be solved and enable the user to objectively compare and choose the solution best suited to his winery:

- What is the harvest schedule?

- What are the characteristics of the vat room?

- What are the heating requirements?

- What thermal equipment is available or can be provided?

Operation and implementation of an installation

Before the installation is commissioned, it must be approved in the same way as a building or a house. Each component installed must correspond to the initial proposal, which will have been validated by a design office or consultancy body.Hydraulic systems must be rinsed before use to remove any metal or plastic residues that could cause the system to malfunction. They are then bled to remove any air residues contained in the system.

The networks must then be pressure tested, at around 2 bars above the operating pressure. This operation checks that there are no potential leaks. It must be carried out before any insulation, which could mask a possible leak and eventually damage the insulating material or other parts of the installation (corrosion, dirt).

If necessary, the water used in the circuits should be treated for limescale and iron, to prevent deterioration of the network and slow down any drop in exchanger performance.

All system components (pumps, piping, hoses, valves, solenoid valves, fittings, etc.) must be able to withstand water temperatures of 5 to 70°C, condensation and SO2 vapours over the long term without damage or corrosion.

Initial start-up must be carried out by the installer. The installer must supply all the documentation for the appliances, as well as a manual for commissioning and using the system.

It is also advisable to include a contract for the annual re-commissioning of the system, including all the necessary checks (purging, watering, pressure testing, sensor calibration, start-up, etc.).

The system should also be designed so that users with the necessary skills can carry out standard replacement of certain parts themselves (solenoid valves, regulators, sensors). These components must be easily accessible. A set of spare parts can be supplied with the installation.

Hygiene

Before and after each use, all heat exchangers in contact with must, grapes and wine must be cleaned, disinfected and rinsed with water and products suitable for oenology, in compliance with the recommendations of each manufacturer and the regulations. Heat exchangers are subject to temperature differentials and scale build-up very quickly.The usual cleaning method is the same as that used for descaling stainless steel tanks. For internal or "belt" heat exchangers, it should be carried out as soon as the tank is drained and, if possible, after applying a "thermal shock" by circulating very hot water (70-80°C) through the exchanger. This operation removes the fresh scale from the exchanger. For external exchangers, the complete heat treatment circuit is used, with circulation of descaling liquid and then disinfectant in an open or closed circuit, followed by vigorous rinsing. Hot water, with an outlet temperature of at least 80°C, is also very effective for removing scale before using a chemical method.

The operation must be rigorous.

Environment and regulations

The refrigeration industry is currently undergoing major upheaval as CFCs are phased out and HCFCs (R22), which are currently widely used in cooling units in wineries, are gradually replaced. This replacement will take place until 2013, when HCFC production must be stopped and replaced by fluids considered less polluting (ammonia, HFC, CO2, H2O).On the other hand, installations still running on CFCs (R12 or R502) need to be replaced quickly, as production of these fluids is now banned, making it extremely difficult to obtain them in the event of a loss at the installation.

It would already seem advisable to install units compatible with these replacement fluids (R134A, R407A, B and C, R507, R410A).

Safety

Temperature-control equipment is subject to the general rules governing the compliance of cellar equipment. It is essential that the entire electrical supply is protected in accordance with current regulations and that each component of the installation (from production to regulation) has CE certification on the equipment and the user manual.Components of temperature control systems

Temperature control systems, which are highly scalable, are made up of different modules to ensure a high degree of versatility in thermal operations on the one hand, and better monitoring of the processes in progress on the other.The operating principle involves producing a heat transfer fluid (hot or cold) which is then distributed to individual heat exchangers. Each heat exchanger has its own manual or automatic control.

Automatic control can be provided by temperature regulators, a PLC or a microcomputer.

Thermal energy production

This is provided either by a chiller , the operation of which is detailed in the technical presentation in the "Cooling production" section, or by a boiler, the operation of which is detailed in the technical presentation in the "Heating production" section.Distribution

The treated fluid is sent by a pump to various storage, circulation or intermediate exchange elements, then to the exchangers.Find out more about the " Fluid distribution " module.

Controls

The fluid must only circulate in the exchangers when necessary. Each exchanger is therefore fitted with a system of manual or automatic valves. In the case of automatic systems, the temperature is controlled by a sensor and an electronic device that automatically starts or stops the circulation of the fluid depending on the desired temperature.Find out more about the " Regulation and control systems " module.

Regulation and control

These are electronic devices which centralise the information from the sensors and send orders to the control units. In fact, this is the control panel for the entire installation. Find out more about the "Regulation and control units" module.Heat exchangers

These are the devices which are in direct contact with the must, grapes or wine and through which the cold or hot fluids from the general distribution system circulate.These modules are described in detail in the "Equipment" chapters "EXTERNAL EXCHANGERS" and "INTERNAL EXCHANGERS, belts and double envelopes".

Heat production

The 2 types of equipment are :- oil and gas boilers

- electric heaters

The choice of the heat output to be installed should be based primarily on the heat balance. This capacity (once determined) must be based on :

- The desired water temperature (water or brine)

- Energy (electric, gas, oil)

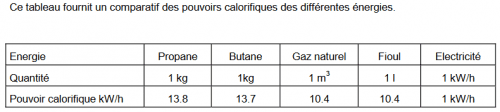

This table compares the heat output of the different energy sources.

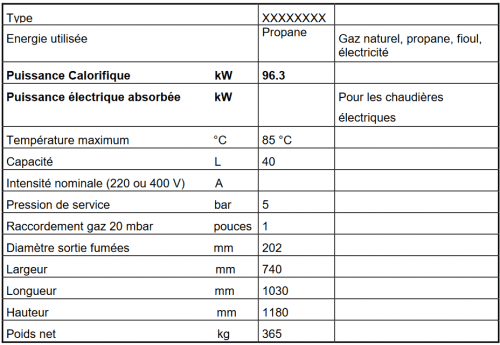

This table contains the main characteristics to be found on a boiler's documentation.

Other criteria that can be taken into account to guide the choice of energy :

- Locally available fuel, with the distance from supply sources posing problems such as cost, which increases with transport costs, storage management and capacity..

- Importance of investment and financing capacity.

- Proposed supply contracts.

- Price of fuel, subscription, meter hire, tank hire, etc

- Guarantee of supply, quantity, quality, etc

- Possibility of contract revision.

Notions of cost

Once the heat balance has been established, you can estimate the amount of heat energy consumed during the winemaking process. To do this, simply multiply the daily hourly output by 24 and divide this quantity of energy by the boiler efficiency (ratio of heat output to power input (called C.O.P. for chillers)). This gives the estimated kW/h consumed per day and therefore the operating cost.Refrigeration production

The 2 types of equipment are- Electric chillers

- Gas chillers

Installation

The initial start-up of an electric or gas chiller can only be carried out by a specialist company. This company must provide the user with all the recommendations for restarting, using and stopping the chiller in the form of a user manual. However, a wintering and restarting contract can be signed with the company.Choice of equipment

The choice of the cooling capacity to be installed should be based primarily on the heat balance. This capacity (once determined) must be based on :- The desired water temperature (chilled water or brine)

- The outside air temperature

- The energy (electricity, gas) and fluid used (R22, R407, R134a, ammonia)

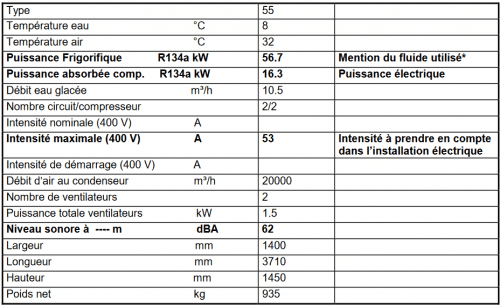

Main characteristics found on the documentation for an electric chiller

Malfunctions

Electric chillers are generally fitted with indicators or lights to monitor their operation.Discharge pressure (H.P. indicator or light)

This is analysed by a pressure switch which controls the efficiency of the condensation process. Any loss of efficiency leading to a rise in pressure is due to :

- Dirty tubes in the condenser

- Reduced air flow (fan failure) or water on the condenser or externally dirty coil.

This is controlled by a B.P. pressure switch. Too low a pressure is due to :

- A lack of refrigerant

- Faulty expansion valve

- A blocked dehydrator

- A defective capacity reduction device.

This is measured by a low temperature thermostat. The main reasons for a low water temperature are as follows:

- Reduced water flow (pump failure)

- A water outlet set point that is too low.

This is measured by an oil pressure switch which gives the difference between the oil pressure in the lubrication circuit and the suction crankcase pressure. Any drop in oil pressure can be caused by :

- Lack of oil

- A faulty oil pump

- Destroyed oil resistance promoting condensation of the coolant in the oil.

Cost concepts

Once the heat balance has been established, it is possible to estimate the amount of cooling and heating energy consumed during the winemaking process.To do this, simply multiply the daily hourly power by 24 and divide this amount of energy by the C.O.P. (Ratio of cooling power to power input (called efficiency for boilers). of the cooling unit. This gives the estimated kW/h consumed per day and therefore the running cost.

Oenological practices: focus on thermal aspects

Summary of the thermal cycles for the different vinifications

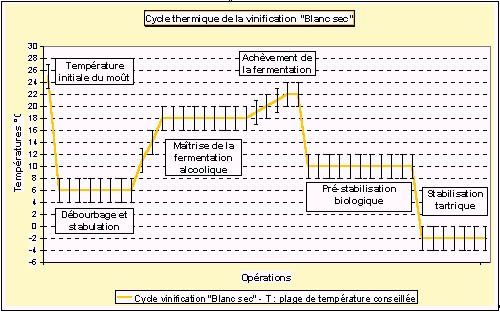

Thermal cycle for "Dry white" vinification

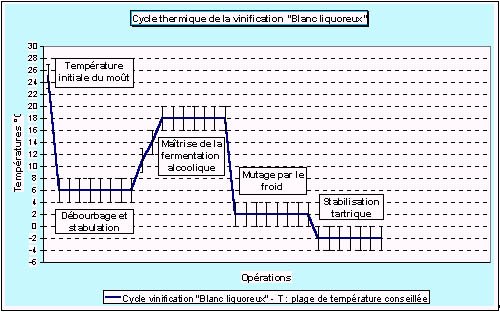

Thermal cycle for "Sweet white" vinification

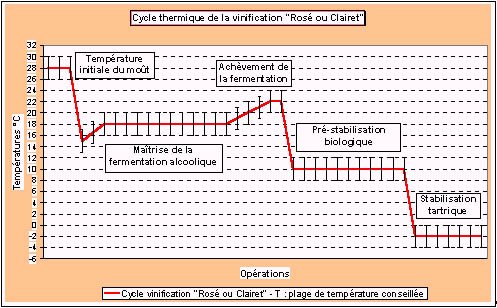

Thermal cycle for "Rosé and Clairet" vinification

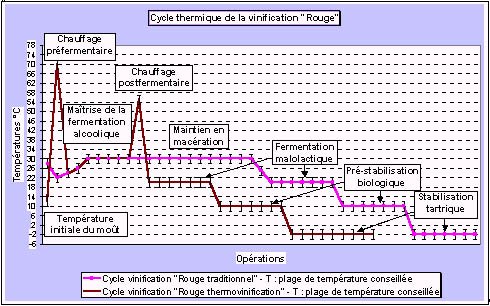

Thermal cycle for "Red" vinification

In each case, the total temperature range is several dozen degrees , with a tolerance of just a few degrees at any given time. What 's more, these cycles can vary widely within the same company, from one vat to another, and from one year to another, depending on the oenological choices made. Finally, and this is the best known but not always the best controlled, during alcoholic fermentation the wine tends to deviate constantly from the desired temperature under the influence of the heat of fermentation or exchanges with the atmosphere.

Given the unpredictable diversity of climatic conditions, the varied but precise optimum temperatures, the heat released by alcoholic fermentation and the spontaneous heat exchanges between the wine and the atmosphere, in order to obtain the ideal temperature at all times, it is necessary to be able to HEAT OR COOL at all times.

Initial cold maceration

Principle

This technique consists of delaying the start of fermentation of the red grapes to encourage exchanges between the skins and the juice and bring out the colour and aromas. The wines are more structured and rounder (aqueous medium, so the pips are not attacked by the alcohol and do not release their excessively hard tannins). M.I.F. takes place as soon as the wine is placed in vats, using dry ice, and lasts for 10 to 15 days.Thermal constraints

Temperature : the harvest is cooled to a temperature of around 5°C, maintained by adding dry ice every day.Cooling must be rapid in order to induce a thermal shock that causes the cell to burst as the skins freeze.

The harvest must be reheated before fermentation can begin.

Some oenological aspects

The harvest must be perfectly healthy and clean.The cellar must be well ventilated to prevent the release of CO2 gas.

However, the harvest is sulphited as necessary to avoid any bacteriological problems.

The gaseous state of the dry ice produces micro-bubbles which homogenise the harvest by internal stirring and protect the vat by saturating the must with CO2.

Careful tasting every day is essential to ensure that fermentation starts when the vat seems 'ripe'.

Settling and stabulation

Principle

After an initial coarse settling period of a few hours at room temperature, the white must is cooled to facilitate static settling. In some cases, the must is kept at low temperature for several days on fine lees (cold liquid stabulation) before fermentation begins.Thermal constraints

Temperature : the wine must be cooled to between 5 and 10°C for extended periods in order to prevent fermentation from starting.Cooling must be rapid, and completed within a few hours of extracting the musts: this often results in significant thermal requirements (available power, exchange surfaces, etc.).

Some oenological aspects

This cooling does not obviate the need for sulphiting - which is always necessary, but at a dose that can be reduced - or enzyming, or bentonite treatment in certain cases.Stricter settling (turbidity < 100 NTU) - in the cold - results in more stripped musts, which can then present fermentation difficulties and produce wines that are too thin. Turbidity > 150 NTU can lead to a risk of coarse flavours.

Cold Liquid Stabulation - at least 4 to 6 days before fermentation - often produces wines that are more aromatic, fatter and longer on the palate, with no particular risks.

Vatting and extraction

Principle

The extraction of colour and tannins from red wines during vatting is greatly enhanced by temperature. The maximum practical temperature to aim for is limited only by its inhibiting effect on alcoholic fermentation, above around 35°C.Temperature constraints

In the Bordeaux region, depending on climatic conditions, heating red wines during the vatting period is useful - or essential - about 1 year out of 2, perhaps more, especially in the case of small or medium-sized vats (less than 200-300 hL), made of steel, outside..Early heating, from the time of vatting, helps to "kick-start" fermentation and reduce subsequent heating requirements.

Efficient regulation allows this extraction to be optimised without the risk of stopping alcoholic fermentation.

Some oenological aspects

Controlling vatting temperatures does not dispense with sound oenological practices: aeration, pumping over, monitoring fermentation, etcA high vatting temperature, maintained for a long time at over 30°C, leads to wines that are more colourful, more tannic and more fleshy, particularly in a "cold year". This practice is best applied to wines for laying down.

Vatting can be supplemented, and sometimes replaced, by other, more energetic "thermal" techniques: thermovinification by heating the harvest to around 70°C before fermentation, or hot final maceration at around 50°C - 55°C after alcoholic fermentation and before malolactic fermentation, for 12 to 24 hours. These last two techniques require a great deal of care (shelter from the air, sanitary conditions, etc.).

Alcoholic fermentation

Principle

Fermentation at a moderate temperature, around 18-20°C, preserves the aromas coming from the grapes and allows the formation of "fermentation aromas" that respect the typicity of the wines and therefore produce new, more aromatic wines.Thermal constraints

Most often, in the Bordeaux region, the fermenting wines have to be cooled to keep the temperature within 18-20°C. The total thermal requirements of a winery vary greatly (ambient temperature, volume and materials of the vats, etc.) but are always much higher than the average requirements. Good control of the rate at which grapes are brought into the winery and systematic temperature regulation , from the time of vatting, can greatly reduce these 'peak' requirements.Some oenological aspects

Optimum temperature is especially important during the first part of fermentation, up to a density of around 1.010.At the end of fermentation, it is safe and sometimes useful to allow the temperature to rise to 20°C or a little more to facilitate the complete transformation of the sugars.

Much lower fermentation temperatures, around 15°C or less, possibly using "cryophilic" yeasts, do not seem to give improved results in most Bordeaux cases.

These fermentation aromas are very useful, but they diminish slightly with ageing, so they cannot replace the grape 's 'primary aromas' , which remain essential.

Finishing fermentation

Principle

Alcoholic fermentation of the last grams of sugar and malolactic fermentation only take place at a sufficient temperature, around 18-22°C. Significantly higher temperatures are unnecessary and may encourage certain bacterial changes.Thermal constraints

More often than not, in the Bordeaux region, the wines have to be warmed up to keep them at a sufficient temperature, especially when fermenting in small, steel or outdoor vats, or in late years..Thermal requirements are almost always very low, limited to compensating for heat loss to the atmosphere.

Some oenological aspects

Sluggish completion fermentations are both a cause of concern for the winemaker and a risk of quality loss for the wines.Despite its importance, temperature is not the only important factor. Excess SO2, a lack of 'survival factors', the accumulation of fermentation inhibitors (C8 and C10 acids), insufficient yeast or bacterial populations, etc. all need to be controlled, often preventively

In all cases, thermal interventions should be carried out as a preventive measure, before any difficulties arise in completing alcoholic fermentation or developing malolactic fermentation: curative interventions are more costly, less effective and even dangerous.

Mutage

Principle

Mutage in sweet white wines involves stopping alcoholic fermentation when the desired balance of alcohol and residual sugars has been reached. The most commonly used method is to add a massive dose of SO2 all at once. Cold temperatures make it easier to stop fermentation and save SO2.Thermal constraints

Lowering the temperature of the fermenting must to between 5 and 10°C within a few hours slows down alcoholic fermentation.Some oenological aspects

As the yeasts remain alive, sulphiting must be extensive and carried out quickly to prevent fermentation from resuming when the temperature rises.SO2 is all the more effective when there are fewer yeasts to inhibit and when they are less active; cold contributes to this. It is advisable to reduce the number of yeasts before or after mutage, by racking or by any other means: centrifugation, filtration.

In any case, if these wines are to keep well, the yeasts must be eliminated as quickly as possible.

Biological pre-stabilisation

Principle

Cooling wines that have completed their alcoholic (and malolactic) fermentation facilitates their biological stabilisation by promoting the inhibition and precipitation of yeasts and bacteria that have become useless and then harmful.Thermal constraints

Early cooling of the wines after fermentation means that the winter chill can be reproduced at will, either too late or insufficiently. It is advisable to bring the wine down to 10°C or less in a few days and leave it there for several days.Treatment is particularly simple and economical in vats fitted with "internal" heat exchangers (immersed, double-walled). The power required is low because the treatment is spread over long periods, which are often already cold.

Some oenological aspects

This practice is highly recommended for purifying - pre-stabilising - all wines, as soon as the free SO2 has been adjusted to a value that is sufficient for the wine to be cooled, in full, well-sealed vats.For sweet white wines, cooling can be carried out - at as low a temperature as possible - before, during and/or after mutage.

This cooling can be combined with easier treatments (fining, filtering) on more stripped-down wines.

It in no way replaces specific tartaric stabilisation treatments and can sometimes reduce their effectiveness.

Heat stabilisation of wines

Principle

Heating wines to a high temperature destroys yeasts and bacteria and ensures their biological stability: this is known as pasteurisation, thermolisation, etcThermal constraints

The thermal conditions to be applied (temperature and duration) vary with the wines (degree, number of germs) and must be determined in each case (e.g. number of "pasteurisation units").Temperatures of around 50-70°C are often reached, depending on the type of pasteurisation. These temperatures require considerable power and well-adapted facilities for cooling the wines.

This operation must be carried out in an airtight environment, under the supervision of an oenologist and using suitable equipment.

Some oenological aspects

Heat treatment at high temperatures is relatively rare, especially for quality wines.They always require a great deal of oenological care: SO2, CO2, prevention of aeration, sterility after treatment, colloidal stabilisation, taste checks, etc. There must be no recontamination.

Tartaric stabilisation

Principle

At low temperatures - around 0°C and below - supersaturated potassium bitartrate in the wine precipitates out and is eliminated by filtration; this eliminates the risk of tartaric precipitation in the bottle.Thermal constraints

Three main techniques are used today:- Cold storage for 15 to 20 days at around -5°C, sometimes with intermediate filtration.

- Contact" treatment for a few hours at around 0°C, with mass seeding with micronised potassium bitartrate.

- Continuous treatment, in a few tens of minutes, at around 0/-5°C, with or without inoculation, using specialised equipment.

Some oenological aspects

The success of these treatments requires rigorous oenological control (stability tests, saturation temperature, mini-contact, etc.) before and after treatment.All the traditional oenological parameters (oxidation, SO2, CO2, etc.) must be controlled to ensure that the organoleptic qualities of the wines are fully respected.

It is well suited to red wines, where it also stabilises the colouring matter.

Benefits of applying it to young wines:

- more effective (over-saturation)

- gives the wine time to "recover" from the treatment

Ageing and conservation of wines

Principle

Wine maturing and conservation are sensitive to temperature conditions; high temperatures accelerate biochemical processes that are slowed down by lower temperatures. Optimum values vary greatly depending on the wine and the way it is marketed.Thermal constraints

Wine maturing (in vats or barrels) often benefits from temperatures that vary, but not excessively, over the course of the year, for example between around 5 and 20°C. Constant temperatures slow down the maturing process.Bottled wines benefit from the opposite conditions: temperatures that are as stable as possible, e.g. between 10 and 15°C, while avoiding values that are too low and could even freeze (e.g. January 1985) or too high, exceeding 18-20°C.

Temperature control always starts with adequate insulation of the premises. Ventilation, airing and air-conditioning of the winery require serious thought. These two environmental factors, temperature and humidity, are practically always inseparable and must be respected simultaneously. Their importance varies depending on whether the wine is stored in vats, bottles or barrels.

Although we currently have a great deal of high-performance thermal equipment, our knowledge of oenology in this area is very limited and deserves to be studied in greater depth.

Experiment

See the list of experimentsSee more - Distribution des fluides - 2019

- Organes de régulation et de pilotage pour les installations de maitrise des temperatures - 2019

- Bilan thermique - 2019

- Etude de la macération préfermentaire à chaud - 2013

- Macération préfermentaire - 2013

- La thermo-détente : nouvel outil de thermovinification - 2009

- Bilan thermique et énergétique d'une cave - 2007

- Evaluation du procédé de vinification par flash détente dans le bordelais - 2006

- Maitrise des temperatures au chai et cuviers - 2004