Leaf remover

Leaf thinning involves removing some or all of the leaves on the vine in the fruit-bearing zone. The definition is simple, but the optimum conditions for carrying it out are difficult to master. The operating principles are varied, particularly for machines that have recently arrived on the market. There are a number of criteria that need to be understood and adhered to if quality leaf removal is to be achieved.

Manually, leaf removal from vines requires a great deal of manpower and is therefore very costly. The technique pays for itself in the time saved by mechanisation compared with manual leaf removal.

Manually, leaf removal from vines requires a great deal of manpower and is therefore very costly. The technique pays for itself in the time saved by mechanisation compared with manual leaf removal.

Why thin out the leaves?

First of all, it should be pointed out that the aim of vineyard management is to obtain sufficient, but not excessive, foliage. In the case of plots that are too vigorous and therefore too leafy, leaf thinning is a corrective technique to :Improve health

By removing the leaves, the foliage is less crowded around the bunches, which benefit from better aeration. The grapes dry more quickly. The result is a reduced risk of fungal diseases such as grey rot and downy mildew developing in at-risk grape varieties and yearsThe bunches of grapes are more accessible, making it easier for the products to penetrate during localised treatments. This can improve the effectiveness of product applications on bunches.

Improving harvest quality

By removing the leaves that cause shade, the grapes are more exposed to the sun and heat. The result is better synthesis of phenolic compounds and aromas. If leaf removal is carried out correctly, red wines are more tannic and white wines more aromatic. However, excessively high temperatures in the bunches can have a negative impact on the synthesis of aromas. It is important to maintain sufficient leaf area so as not to limit the concentration of sugars in the grapes.Saving time at harvest time

In the case of manual harvesting, thinning out the leaves close to the harvest increases the yield of the pickers by unmasking the bunches. Carried out mechanically on both sides of the rows 24 to 48 hours before picking, the aim is to remove as many leaves as possible. Mechanical leaf removal reduces harvesting time by 20-30%. The leaves should not be removed too early so as not to interfere with the final ripening of the grapes, and to avoid the risk of grey rot due to injuries to the berries.It is useless and harmful to thin out the leaves late on a vine that is to be harvested mechanically. The foliage acts as a mattress, keeping the vegetation in place and allowing effective shaking without bursting the berries too much.

How should the leaves be removed?

Which plots should be thinned out?

Those with too much foliage, which limits the ripening of the grapes and allows a microclimate favourable to the development of disease to be maintained.Some grape varieties are more susceptible to disease than others and should be thinned out as a priority.

The fruit-bearing zone must be perfectly defined. To achieve this, the trellising must be impeccable, as any irregularities in the growth pattern are likely to increase the risk of injury.

This is why it is important to take into account the characteristics of each region (growing methods, climate, grape varieties, etc.) in order to define the optimum method of leaf removal, vineyard by vineyard.

Leaf thinning should not be too severe. Leaves should be removed from one side of the row only, particularly the side facing the rising sun. This limits the risk of burning and helps the dew to dry out properly.

Hand or machine leaf removal?

The choice of method involves a number of qualitative and economic criteria. Manual leaf removal is more expensive but less damaging to the bunches. Today's machines work in different ways.When should the leaves be removed?

Four dates can be defined in relation to different stages of vine growth: flowering, fruit set, bunch closure and veraison.IFV trials show that early leaf thinning is preferable for the following reasons:

- better results in combating grey rot

- gradual exposure of the bunches and partial coverage by the internodes to limit the risk of scalding

- greater polyphenolic potential for vines thinned out early

Power source for mechanical leaf removers

Hydraulic feed

The functions that may require a hydraulic source are: driving the fan propeller or turbine, manoeuvring the height, width, inclination, retraction and pivoting of the leaf remover head.

The hydraulic circuit can be fitted with an oil flow regulator.

The hydraulic circuit can be fitted with an oil flow regulator.

Tractor hydraulic power unit

Tractor hydraulic system supplying the leaf remover

The leaf remover is dependent on the tractor's hydraulics:

Note: if the leaf remover is fitted with a hydraulic distributor, a SE hydraulic connection is sufficient.

The leaf remover is independent of the tractor's hydraulics: it is fitted with a hydraulic power unit (this can be used for other equipment).

- The tractor must provide sufficient oil pressure and flow.

- The tractor must be equipped with the necessary single-acting (SE) and double-acting (DE) hydraulic connections.

Note: if the leaf remover is fitted with a hydraulic distributor, a SE hydraulic connection is sufficient.

The leaf remover is independent of the tractor's hydraulics: it is fitted with a hydraulic power unit (this can be used for other equipment).

Power supply via PTO

The PTO can be used to drive the turbine, to drive an independent hydraulic unit or to operate the compressor in the case of pneumatic leaf removers.The tractor must have sufficient minimum engine power (given in hp and kW).

Leaf removers are designed to operate at an engine speed of 540 rpm. Some manufacturers use the PTO to vary the speed of rotation of the turbine and therefore the suction power.

In this case, the engine speed must not exceed 540 rpm.

- the tractor's electricity can be used for certain electrical or electro-hydraulic adjustments and for electrical contacts, via a special circuit

- gas is used to heat the radiant of thermal leaf removers, with 2 13 kg propane cylinders.

Towing system

Leaf removers can be mounted on inter-row tractors, high-clearance tractors, grape harvesters or crawler tractors. They are mounted on a chassis either in-between the wheels, at the front or at the rear of the 3-point mounted tractor (possibly on skids, wheels or bogie wheels) or on a pendulum bracket.Some leaf removers are sold bare-head, for self-assembly (the tool holder is sometimes offered as an option).

Pivoting the remover head

Pivoting the remover head is an important feature of single-head removers for single-sided stripping. It allows the head to be moved to the other side when changing rows, thus avoiding unworked paths. This operation is performed by a hydraulic or electric cylinder.Principles of adjustment

Positioning the remover head at the fruit-bearing zone

This involves adjusting the height and width to adapt the remover to the height of the trellis and the width of the rows. These adjustments are made on the leaf remover or straddle frame. They are either manual or controlled by hydraulic or electric cylinders.

Influencing the rate of leaf removal

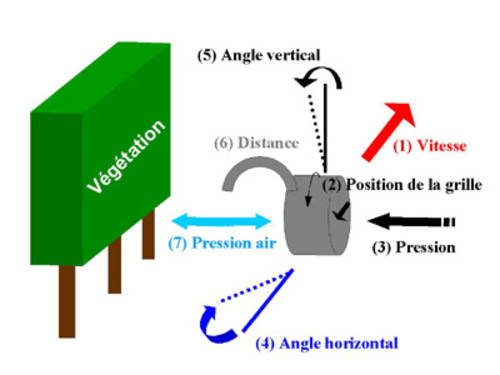

The following diagram summarises the different adjustment options that influence the rate of leaf removal.

(1) - Tractor forward speed

(2) - Rotation or translation of the protective grille

Pivoting around the central axis of the remover head assembly in the case of removers with 2 fans

(3) - Pressure of the remover head on the vegetation (support force)

(4) - Horizontal angle of attack between the remover head and the trellis

(5) - Vertical angle of attack (or inclination) between the remover head and the trellis

(6) - Distance between the feeler and the trellis

Distance between knife and grid

Adaptation to row width

(7) - Air pressure or vacuum on the foliage and speed of rotation of the air jets in the case of pneumatic removers

(2) - Rotation or translation of the protective grille

Pivoting around the central axis of the remover head assembly in the case of removers with 2 fans

(3) - Pressure of the remover head on the vegetation (support force)

(4) - Horizontal angle of attack between the remover head and the trellis

(5) - Vertical angle of attack (or inclination) between the remover head and the trellis

(6) - Distance between the feeler and the trellis

Distance between knife and grid

Adaptation to row width

(7) - Air pressure or vacuum on the foliage and speed of rotation of the air jets in the case of pneumatic removers

(5)

(2)

(3)

(2)

(6)

Driving and automation

The driver's involvement in making the various adjustments can be divided into several categories, depending on the degree of automation. In all cases, for all removers and whatever their adjustment possibilities, the driver's experience and application are essential.Adjustments are said to be " a priori " when the driver has to make them manually before getting on the tractor.

Settings are said to be ' semi-automatic ' when they are accessible from the tractor cab via a control box and can be modified during work.

Adjustments are said to be " automatic " when the electromechanical sensor systems correct the position of the remover head on the trellis according to the density of the vegetation or the position of the tractor, without any intervention by the driver.

Experiment

See the list of experimentsSee more