Plate filter

The plate filter is an essential tool in oenology, for clarifying and sterilising wines. Made up of vertical trays with filter plates in between, this device guarantees effective filtration. The main components include a frame, an opening and closing system and pressure gauges. Used for pre-filtration, fine filtration or sterilisation, the plate filter can be adapted to a variety of needs, thanks to stainless steel, plastic or aluminium plates.

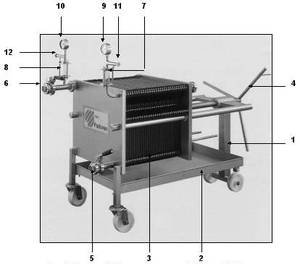

Plate filter

The plate filter is made up of a variable number of vertical plates between which the filter plates are inserted.Presentation of a plate filter

1 - frame (fixed or mobile)

2 - collection tray

3 - plates

4 - opening and closing system

5 - filter inlet

6 - filter outlet

7 - inlet sight glass

8 - outlet sight glass

9 - inlet pressure gauge

10 - outlet pressure gauge

11 - raw wine sample

12 - filtered wine sampler

1 - frame (fixed or mobile)

2 - collection tray

3 - plates

4 - opening and closing system

5 - filter inlet

6 - filter outlet

7 - inlet sight glass

8 - outlet sight glass

9 - inlet pressure gauge

10 - outlet pressure gauge

11 - raw wine sample

12 - filtered wine sampler

Main components

The trays

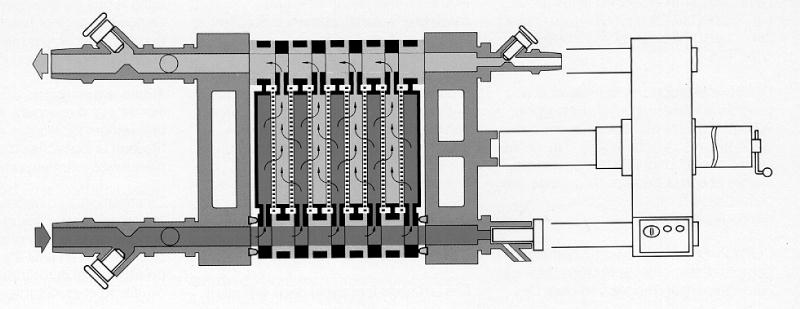

The classic filtration diagram includes :- a fixed head plate

- a mobile tail plate

- the filtration plates, made of stainless steel, plastic (noryl) or, more rarely, aluminium, are mounted in parallel

Simple filtration on plates

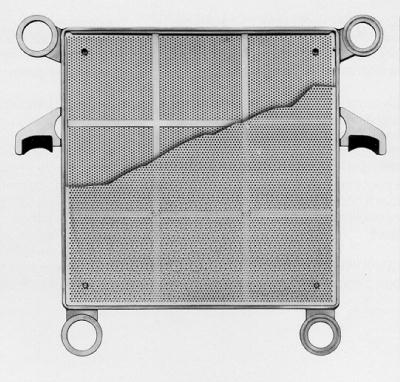

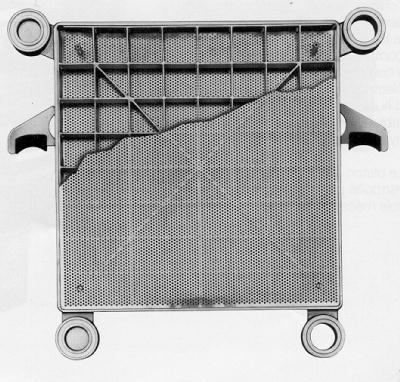

Steel filter plate

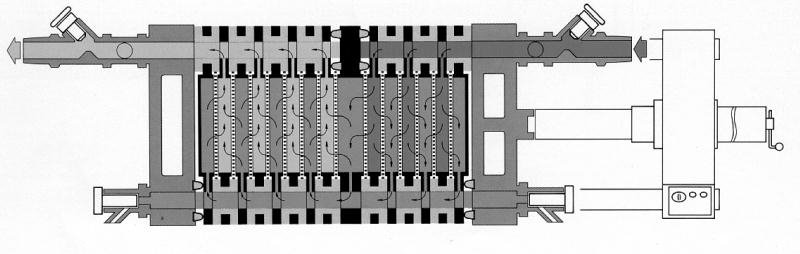

Special case: double filtration

This involves installing a bypass device to separate a filter into two successive filtering sections. This operation can be carried out using a bypass plate or an inversion chamber.Examples of use :

- pre-filtration / fine filtration

- fine filtration / sterilising filtration

Double filtration on plates

Bypass plate

In the case of double filtration, the surface ratio between the 1st and 2nd filtration stages should be approximately 60/40, as it is necessary to respect the flow rates corresponding to each category of plate used.

The efficiency of the filter depends on the ratio of surfaces and plates used.

The plates

Filter plates are classified into three categories:- roughing plates

These are used for pre-filtering new wines to eliminate some of the cloudiness. The filtrate is often not immediately ready for consumption.

These plates have a high filtration rate and high yield. They are being used less and less in favour of filtration with additives. - clarifying plates

These are only used on wines that have been properly stripped, with little cloudiness (only a few or tens of NTU). Depending on the type of plate used, satisfactory clarity can be achieved. When used correctly, they significantly reduce the micro-organism population. - sterilising plates

They filter out germs by retaining micro-organisms, yeasts and bacteria. Logically, these plates are used before the bottling machine.

Although widely used, these plates are competing with both lenticular and membrane filters.

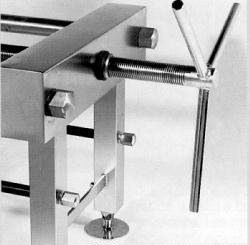

Clamping the plates

Manual system - Screw (most common).

Automatic system - Hydraulic closing system (for large filters, particularly 60 x 60 plate filters).

Technical requirements

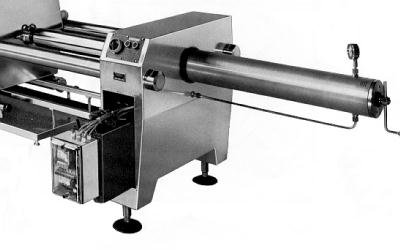

Choice of feed pump

Often overlooked, the feed pump must be able to adapt the flow rate to the number and type of plates used, without jerking.Pumps fitted with a flow variator are best suited to filtration conditions, while piston pumps should be avoided as they produce pressure surges.

Installation of a By-Pass

A device that recycles filtered wine to the pump suction.An essential part of the filtration process, it is always placed at the filter outlet.

The by-pass is fitted with a safety valve set to the pressure that must not be exceeded on the plates.

It ensures that the filter operates smoothly by reducing jolts, and compensates for work constraints during bottling (clogging, bottling machine stoppages).

Before starting filtration, it is essential to consider the following factors:

- the number of plates to be used

- the mounting direction of the plates

- the number of plates to be used

- maximum flow rate

- differential precision

- filtration volume / cycle

Filtration control

Before starting filtration, it is essential to :- determine the number of plates to be used. This depends on the minimum flow rate required, particularly in the case of pre-draft filtration (see calculations in the "Lenticular plates and modules" chapter)

- ensure that all the plates are fitted. A filter plate has a more or less corrugated surface on one side and a smooth surface on the other, bearing the manufacturer's references. The liquid to be filtered must enter the plate on the corrugated side, while the filtrate leaves the plate on the smooth side bearing the identification marks.

- wash the plates with water to eliminate the particular taste imparted by the plates. This washing should be done at a moderate flow rate (e.g. 20 l/h/plate 40X40 cm) and at low pressure. When the plates are properly wetted, tighten the filter pack. Smell and taste the water as it comes out of the filter to make sure it is properly cleaned.

Filtration parameters

To operate plate filtration, the following conditions must first and foremost be respected:Maximum flow rate

Expressed in I/m²/h by the manufacturers, conversion to l/plate/h is more practical.It varies according to the type of plate.

Roughing plates (pre-filtration)

40 x 40 cm 120 to 140 l/plate/h60 x 60 cm 300 to 330 l/plate/hour

Clarifying plates (fine filtration)

40 x 40 cm 70 to 80 l/plate/h60 x 60 cm 150 to 180 l/plate/hour

Sterilising plates (low-germ filtration)

40 x 40 cm 45 to 60 l/plate/hour60 x 60 cm 105 to 125 l/plate/hour

Differential pressure

This is the pressure difference (ΔP) between the filter inlet and outlet.The differential pressure tells us how clogged the plates are.

Each type of plate accepts a specific maximum working pressure that it is imperative to monitor to respect the integrity of the plates and avoid any leaching phenomena.

Roughing plates : ΔP max = 2.5 bars

Clarifying plates : ΔP max = 1.5/2 bars

Sterilising plates: ΔP max = 1/1.2 bar

Clarifying plates : ΔP max = 1.5/2 bars

Sterilising plates: ΔP max = 1/1.2 bar

Filtration volume / cycle

The length of the cycle, expressed in hl (volume not to be exceeded), is on average equal to 6 to 8 times the maximum volume that can be filtered per hour.Example:

Clarifying plates 40 x 40 cm

Number of plates: 20

- Maximum filtration rate = 80 l/plate/h i.e. 16 hl/h

- Cycle length: 16 x 6 to 8 = 96 to 128 hl

Note: The above figures are average values. It is essential to refer to the manufacturer's information for each type of plate and to take into account the "load" of wine to be filtered.

Troubleshooting

Wine is leaking

- The plates are incorrectly tightened.

- The plates are not sufficiently soaked.

The pressure rises very quickly (filtration cycle too short)

- The porosity of the plates is too low.

- Use more suitable plates.

- Filterability of the wine is poor.

The wine is leaking

- The differential pressure limit has been reached.

- Check that the plates are correctly fitted.

Sterilising filtration control is poor

- Improve filter sterilisation.

Note: When the time between 2 filtration cycles exceeds 48 hours, it is necessary to sterilise the unit after the first filtration and a second time just before the second filtration. This prevents the filtered micro-organisms from multiplying and penetrating the plates.

We recommend removing the used plates immediately after filtration.

We recommend removing the used plates immediately after filtration.