Filtration medium

Filtration substrates are characterised by their permeability, expressed in darcies, classifying the additives as fast, medium, slow and very slow. The density of the cake, measured in g/cm³, indicates the porosity of the filter material. Particle size distribution and porosity influence permeability and particle retention capacity.

Common substrates include diatomaceous earth, perlite and cellulose; each with specific properties of density, moisture and security. Retention mechanisms include sieving, depth effect and adsorption.

Common substrates include diatomaceous earth, perlite and cellulose; each with specific properties of density, moisture and security. Retention mechanisms include sieving, depth effect and adsorption.

Characteristics of filtration media

Characterisation of additives

Permeability

Property of a substance to allow a liquid or gas to pass through more or less easily.It is therefore the greater or lesser ease with which a given porous material will allow a liquid to pass through it.

Permeability is expressed in darcies.

Definition of darcies: A porous material has a permeability of 1 darcie when a fluid with a viscosity equal to 1 centipoise flows through it at a rate of 1 cm3 per 1 second per cm² of cross-section under a pressure gradient of 1 atmosphere per 1 cm thickness of admixture.

One darcie corresponds to a theoretical flow rate of 36 m3/h/m² of filtering surface, under the above conditions.

The darcie is used to classify filtration aids (indicative values).

- Fast filtering agents: > 2 darcies

- Medium filtering agents: 1 to 2 darcies

- Slow filtering agents: 0.1 to 1 darcies

- Very slow filtering agents: 0.02 to 0.1 darcies

Cake density

This is the mass of additive contained in a volume of wet filter media.The cake density reflects the porosity of the adjuvant cake formed on the filter support. This criterion makes it easy to assess the limit to the duration of a cycle as a function of the space offered to the cake between the filter elements.

It is expressed in g/cm³.

- Diatomaceous earth: from 0.33 to 0.43 g/cm³.

- Perlites: from 0.13 to 0.36 g/cm³.

Particle size distribution

This is established by sieving the admixture on standardised sieves, and the fractions retained (rejects) are quantified and expressed as a percentage by weight per mm size range. This ensures optimum permeability for a given retention threshold and good compressive strength.Porosity

This is the volume of void in relation to the total volume.It is expressed as a percentage.

Filtration rate per unit area

The filtration rate per unit area.

It is expressed in l/m²/min and gives an idea of the practical progress of filtration.

PH value

Calcined diatomaceous earth: 6 to 8Sintered calcined diatomaceous earth: 8 to 10

Density

The density of diatomaceous earth is between 0.27 and 0.42.Moisture content

Most diatomaceous earth has a moisture content of between 0.05% and 1.28%.Calcined diatomaceous earth must have a moisture content of less than 2%.

Sintered calcined diatomaceous earth must have a moisture content of <0.5%.

Perlites have a moisture content of around 0.1%.

Cellulose has a moisture content of 5 to 10%.

Retention mechanisms

Screening

All particles larger than the pores in the filter layer are mechanically retained. The lower the permeability of the additive, the tighter the sieving effect and vice versa.Effect at depth

When the turbid liquid passes through the adjuvant layer, solid particles are retained deep down in the bends of the circulation channels.Adsorption

This is an electrostatic phenomenon that allows particles with diameters smaller than those of the circulation channels to be retained.Mixed pre-coatings

Ready-to-use, they are used directly on the filter support in place of the first diatomaceous earth precoat. They simplify the application of the precoat and reduce the time needed to produce it.They can be composed of the following materials

- white or pink diatomaceous earth

- cellulose fibres

- synthetic fibres

- cotton fibres

Storage advice

Store additives in a dry place away from odorous products (pesticides, fertilisers, fuel oil, etc.) which may be adsorbed.Diatoms

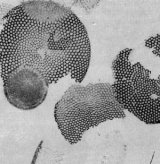

Diatoms under microscope (x400)

Characteristics

Diatom ore (or diatomite or kieselguhr) is a siliceous rock made up mainly of the remains of fossilised skeletons of diatoms, microscopic unicellular algae of marine or lake origin.There are thousands of species of diatoms, but they all produce very light, highly porous products.

There are two groups: centric diatoms and pinnate diatoms.

Safety

Diatoms contain a level of cristobalite that is irreversibly harmful if inhaled, requiring effective protective measures for users and the environmentDiatom correspondence table

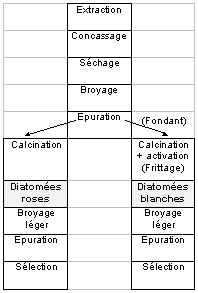

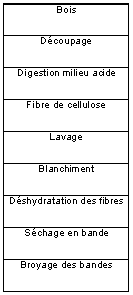

Diatoms - Manufacture

Perlite

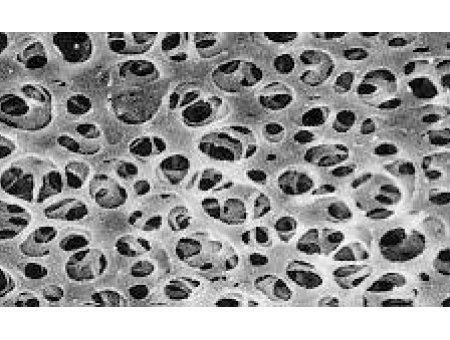

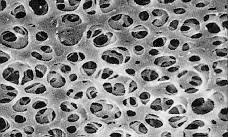

Perlite under the microscope (x1800)

Characteristics

Perlite is a vitreous rock of volcanic origin. The grain expanded by heating has a very fine honeycomb structure.Perlite additives have the advantage of forming more porous cakes than diatomaceous earth, resulting in longer cycles.

The low density of certain perlites means that smaller quantities of admixture can be used.

On the other hand, perlite is abrasive, so the equipment wears out more quickly.

Safety

Perlite is a complex natural silicate of aluminium, potassium and sodium that does not undergo any chemical treatment. Perlite dust does not cause any illnesses or harmful effects.Perlite correspondence table

Perlite - Manufacture

Cellulose

Characteristics

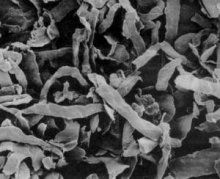

Cellulose is the main component of plant cell walls.Under the microscope, it appears as long, whitish fibres.

By varying the intensity of processing, a very pure product can be obtained with a range of different grain sizes and densities.

The different celluloses on the market are characterised by the length of the fibres that make them up. Specific preparations of cellulose with added diatomaceous earth are used to form the pre-coat (alluvial filtration). The cellulose ensures the integrity and strength of the filter cake throughout the cycle. Cellulose also helps to maintain good drainage on the filter media used.

In most cases, prior swelling of the cellulose in water is recommended before use.

Cellulose fibres under the microscope

Average fibre length and diameter

- Fibre length: approximately 20 to 110 µm

- Average diameter: approximately 15 to 20 µm.

Cellulose - Manufacture

Plates

Plates are made up of several of the following elements:- cellulose

- diatomaceous earth

- synthetic fibres

- cotton fibres

- perlite resin

- silica

Retention mechanisms

The pores of the plates are asymmetrical, with the large pores on the inlet side. The liquid to be filtered passes through the plate along countless channels. This depth filtration has several retention effects:

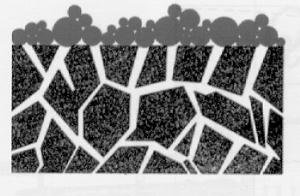

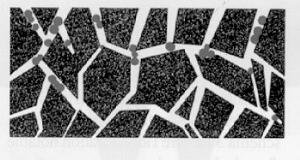

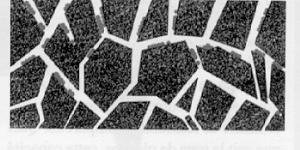

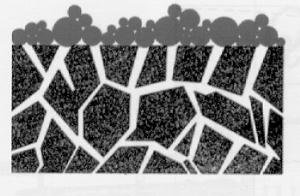

Retention of particles at the surface (sieving effect) - Source Seitz

Retention of particles inside (depth effect) - Source Seitz

Retention by adsorption (Zeta potential of impurities smaller than the size of the channels) - Source Seitz

Categories

Manufacturers classify filter plates into 3 categories:Roughing

- flow rates of 120 to 140 l / h / plate

- low tendency to clogging

- used for initial filtration, instead of filtration with additives

Clarifying

- flow rates of 70 to 80 litres per hour per plate

- use after filtration with additives

Sterilising

- flow rates of 40 to 60 litres/hour/plate

- for use after very tight filtration on adjuvant, before bottling or before membrane filtration

Important parameters

Filter surface

The plates are available in several sizes:- 20 x 20 (cm x cm), for laboratory use

- 40 x 40 (cm x cm), most commonly used

- 60 x 60 (cm x cm), mainly for the trade

For example

100 slabs 40 x 40 -> 14.28 m²

100 sheets 60 x 60 -> 33.33 m²

Flow rate per unit area

Determined by the filler's speed, the maximum flow rate through the filter is constant.The flow rate varies according to the type of plate.

It is generally expressed in l/m²/h.

Example of calculation of the number of plates to equip upstream of a filler:

For an output of 1200 bottles/hour (= 900 l/h).

Or a 40 x 40 filter fitted with clarifying plates.

(flow rate of 70 to 80 l / h / plate).

Number of plates = 900 : 70 = 12.85

A minimum of 13 plates must be installed.

Differential pressure

This is equal to the pressure difference between the filter inlet and outlet and is expressed in bar.The differential pressure (DP) limit specified by the manufacturer must not be exceeded.

Roughing plates : DP = 2.5 bars

Clarifying plates: DP = 1.5/2 bars

Sterilising plates : DP = 1/1.2 bars

Lenticular modules: DP = 2 bars

Clarifying plates: DP = 1.5/2 bars

Sterilising plates : DP = 1/1.2 bars

Lenticular modules: DP = 2 bars

Volume filtered or cycle length

The length of the cycle (in hL) can be 6 to 8 times the hourly filtration rate, with very wide variations.Example : A filter with 100 40 x 40 clarifying plates.

- flow rate: (70 L/h/plate) x 100 = 70 hL/h.

- maximum cycle length = 70 x 6 to 8

i.e. 420 to 560 hL.

Plate correspondence table

Lenticular modules

Lenticular modules are composed of several of the following elements:

- cellulose

- diatomaceous earth

- synthetic fibres

- cotton fibres

- perlite resin

- silica...

Lenticular modules are made up of an assembly of lenses. Each lens consists of a filter medium and a drainage system, the edges of which are sealed by a pressurised thermoinjection process. The lenses are superimposed on a central tube, then compressed and assembled to form a sealed unit.

Retention mechanisms

The retention mechanisms are similar to those used for filter plates and are as follows:

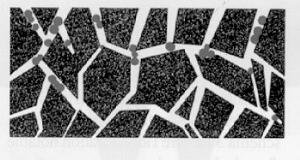

Retention of particles on the surface (sieving effect) - Source Seitz

Retention of particles on the inside (depth effect) - Source Seitz

Retention by adsorption (Zeta potential of impurities smaller than the size of the channels) - Source Seitz

Categories

Manufacturers classify filter plates into 3 categories:Roughing

- low tendency to clogging

- for use as initial filtration, instead of filtration with additives

Clarifying

- for use after filtration with additives

Sterilising

- use after very tight filtration with adjuvant, before bottling or before membrane filtration

Important parameters

Filter surface

Lenticular modules are available in 2 standard diameters:- 284 mm diameter -> 1.8 m²

- diameter 410 mm -> 3.6 m²

Flow rate per unit area

Determined by the filler speed, the maximum filter flow rate is constant for a given media.Recommended flow rates :

- clarifying modules: 1000 L/h/m²

- sterilising modules: 500 L/h/m²

Differential pressure

This is equal to the pressure difference between the filter inlet and outlet and is expressed in bar.The differential pressure (DP) limit specified by the manufacturer must not be exceeded.

Lenticular modules: DP = 2 bars

Volume filtered or cycle length

The average cycle length without regeneration can be up to 200 hL/m².Cartridges

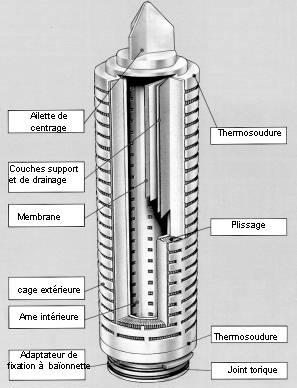

Cartridges are made up of one or usually several membranes mounted on a solid polypropylene support and protected externally either by a fabric or a frame.

Membranes are made from a wide range of materials, including fibreglass, polypropylene, cellulose esters, nylon, polysulphones, etc.

Depending on how the particles are retained, they are classified into 2 groups: surface filters and depth filters.

Membranes are made from a wide range of materials, including fibreglass, polypropylene, cellulose esters, nylon, polysulphones, etc.

Depending on how the particles are retained, they are classified into 2 groups: surface filters and depth filters.

Surface filter membrane under the microscope

Surface filter

The surface filter (or sterilising filtration) is essentially a sieve: only particles smaller than the pore diameter pass through the media (membrane in the strict sense).The thinness of the membrane (less than 1 mm) allows it to be pleated, which considerably increases the filtering surface per cartridge.

Cartridge filter diagram

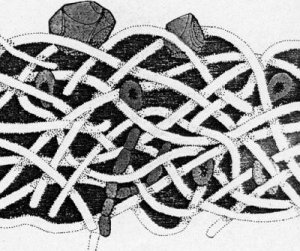

Depth filter

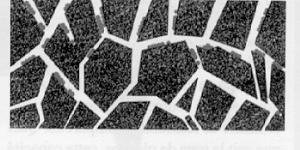

A depth filter consists of a tangle of fibres grouped together in one or more layers up to a few millimetres thick. These fibres are randomly oriented and the space left free defines a series of sinuous channels.The porous structure thus defined is irregular, with the entanglement of the fibres causing the pores to shrink inwards.

In a depth filter, 3 modes of retention come into play.

- Screening: particles larger than the pore opening are retained on the surface.

- Depth retention: smaller particles are intercepted inside the interstices of the fibres.

- Adsorption : By adding positively charged resins (e.g. Zeta+ potential) to the membrane composition, very small impurities are retained by electrostatic adsorption.

Characterisation

Pore size

Absolute retention threshold (in mm) for sterilising membranes with a stable structure and correlated to a bacterial challenge tested with micro-organisms. Each filter is characterised by an average pore diameter with very low variability (see figure 1) (Example: 1 µm ± 0.2 µm). For sterilising filtration cartridges, the stated value can be verified by measurement in situ (integrity test).Nominal or actual retention threshold (in µm) for depth or pleated pre-filters. A pore diameter is known with a wider distribution tolerance.

Distribution curves for surface and depth filters

Porosity

This is the ratio of void volume (pores) to total volume.As a guide:

- Low porosity 15-20

- Medium porosity 50%

- High porosity 80-85%

Height

The height unit is the 10-inch cartridge, i.e. 254 mm.Cartridges are available in 10, 20, 30 or 40 inch sizes.

Filter surface area

This is given in m² per unit of 10-inch cartridge or 254 mm (approximately 0.5 to 0.8 m² / 10 inches depending on the media).Operating pressure

The maximum pressure difference ΔP is generally between 5 and 7 bar, but it is advisable not to exceed 2-3 bar, otherwise regeneration will be difficult.Integrity check

The test ensures that the pore diameter is uniform and checks the overall tightness of the system, and should be carried out before the start of the draw-off, during sterile filtration.In the event of a problem, the absence of this test means that it is not possible to tell whether the incident is due to the integrity of the membrane or to poor sterilisation of the equipment (see the operating procedure in the chapter on cartridge filters).

Regeneration

To ensure a long service life, the membranes must be regenerated at the end of the day or when the pressure difference (P) reaches the limit value (according to the manufacturer's data).The operation is carried out with hot filtered water, in the direction of filtration (co-current) or in counter-current according to the method recommended by the manufacturer (respect the maximum differential pressure indicated for the counter-current) (see the section on cartridge filters).

chemical regeneration

Type of chemical: caustic soda (NaOH) at a concentration of 0.5 to 2%.Procedure: pass half the solution through a waste water system, the other half through a closed circuit (co-current, then static)

- flow rate: max. 3 hL/h per 30" cartridge

- time: 30 minutes

- temperature: 60°C

Rinse thoroughly with cold water after chemical regeneration*

Check that there are no traces of chemical products using test strips; test the integrity of the final membrane filter.

* These procedures are applied in exceptional cases of abnormal clogging. They are given for guidance only and must be validated by the manufacturer.

Neutralisation with citric acid

Type of product: citric acid powder or crystals at a concentration of 1 to 2%.Procedure: prepare a solution of a volume suited to the size of the existing materials. Use a small pump and pass the solution through a closed circuit on the pallet:

- co-current direction

- flow rate: 1 to 3 hL/h per 30" cartridge

- time: 5 minutes

- temperature: ambient

Sterilisation

Sterilisation should be carried out at the start of each filtration cycle, generally using hot water or steam.Choice of filter media

Depending on your requirements, you can choose the type of cartridge.For a low germ content, cartridges with a retention threshold of 0.45 to 0.65 µm are used.

For less sensitive products or less stringent microbiological requirements, pores of 1.2 to 2 µm are used.

A cartridge filtration paddle often consists of a pre-filter (depth or pleated cartridge) followed by an absolute filter.

The size of the various housings must be chosen to match the work rate of the bottling line (see the section on cartridge filters).