Pre-coat filter

The continuous pre-coat filter works by constantly adding filter material to the product being filtered, forming layers that trap unwanted particles.

The main elements of the pre-coat filter include a bell, filter plates, a dosing pump and a mixing tank.

There are different types of pre-coating: horizontal bell, vertical bell, alluvial plates and candle; each with its own advantages and disadvantages.

The precoat, essential for filtration, ensures immediate clarification and makes it easier to break up the filter cake. Regular alluviation improves filtration cycles by delaying clogging and maintaining the porosity of the cake.

The main elements of the pre-coat filter include a bell, filter plates, a dosing pump and a mixing tank.

There are different types of pre-coating: horizontal bell, vertical bell, alluvial plates and candle; each with its own advantages and disadvantages.

The precoat, essential for filtration, ensures immediate clarification and makes it easier to break up the filter cake. Regular alluviation improves filtration cycles by delaying clogging and maintaining the porosity of the cake.

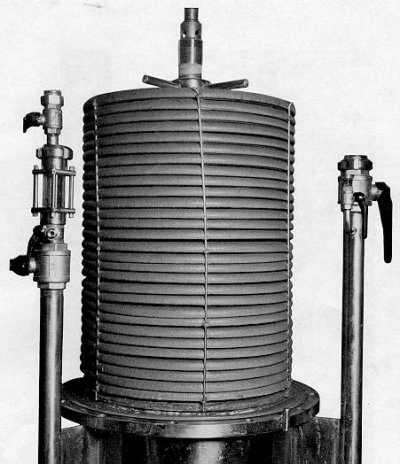

Alluvial filtration

In continuous alluvial filtration, the filtering material is continuously supplied mixed with the product to be filtered. The filter medium forms the filter, in one or more layers, which retains the undesirable particles.Technical

presentation of

a continuous trickling filter

- Bell

- Filtering plate||

- Cake discharge opening

- Motor for plate rotation

- Filtering plate washing ramp

- External residual filtration element (depending on model)

- Dosing pump for filtering aid

- Mixing tank for filtering aid, with agitator

- Main feed pump

- Flow indicator

- By-pass

- |

Main elements

The bell

There are two types of bell: vertical and horizontal.The filter plates

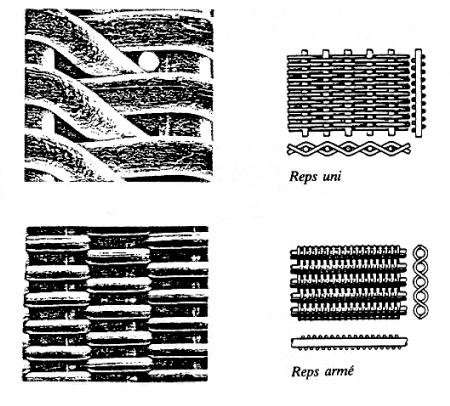

In vertical bells, the trays are either horizontal or vertical.Tray construction

The trays are made up of- :

- a wide-mesh metal frame to support the filtration fabric and drain the filtrate.

- a stainless steel wire or reps fabric. The fabric pore diameters currently encountered are generally between 50 and 120 µm.

Horizontal platforms

Maillaige

reps |

The mixing tank

It is fitted with an agitator.The feed pump

It determines the flow of wine to be filtered.The dosing pump

It ensures that the wine is alluviated.The by-pass

It ensures a partial return of the filtered wine with the wine to be filtered.The different alluvial filters

Horizontal bell and vertical plate filters

The horizontal bell and vertical plate filters are still widely used, but their manufacture has almost been abandoned. | | | || ADVANTAGES | DISADVANTAGES |

|---|---|

| - Both sides of the plates are used | - Significant consumption of water when cleaning |

| - Low space requirement in height | - Significant loss of wine |

| - - |

| cleaning of |

| filter | |

| | | | || | |

| Automatic filter cleaning | - Residual filtration impossible |

| - Easy dismantling of filter elements | - Water gluing impossible |

| - Price often attractive | - No dry extraction of filter cake (pollutant discharge) |

| | | |

| No water gluing | |

| possible | |

| - No dry extraction of filter cake (pollutant discharge) | |

| - Impossibility of changing wine quality | |

| | | - Watertightness problem with the filtration column |

| - Very delicate maintenance of the filter cake | |

Vertical bell and horizontal plate filters

These are the most common alluvial filters. | | | || ADVANTAGES | DISADVANTAGES |

|---|---|

| - Very good stability of the cake; filtration can be stopped without destroying the precoat | - Only one side of the tray is used |

| - Impractical removal of wire elements |

| - Ability to change wine quality without mixing (maximum use of the precoat) | - Ability to change wine quality without mixing (maximum use of the precoat) - Ability to change wine quality without mixing (maximum use of the | |

| precoat | |

| ) | |

| precoat) | - Depending on the brand, sealing problems on the column | |

| - Dry extraction of the cake | - More costly investment |

| - Possibility of gluing to the ea | | |

| - Residual filtration | possible | |

| - Low water consumption for washing | |

| | | |

| - High cycle | length |

| | - Automation capability | |

| | | |

| - Small footprint | | | |

Alluvial plate filters with hollow frames

They are derived from the classic plate filter.Hollow frames are inserted between the filter elements and fitted with suitable support plates. | | | | | | |

| ADVANTAGES | DISADVANTAGES |

|---|---|

| - Very large filtering surfaces | - Delicate maintenance of the cake |

| - No mechanical movements subject to wear | - Impossibility of gluing with water |

| | - | |

| Versatility (use of plates or additives) | - No residual filtration|| |

| - Easy maintenance (solid material) | - Long, tedious cleaning (high labour input) |

| - Long cycle times | - Time-consuming set-up|| |

| | | - Very high filtration cost |

| | | - High filtration residue |

Candle filters

Candle filters are rarely used in oenology. These are vertical bell filters with vertical filter supports. These supports are like "pipes" made either of stainless steel washers stacked on a spindle, or of a stainless steel coil. | | | | | | -| ADVANTAGES | DISADVANTAGES |

|---|---|

| - Very large filtering surfaces | - Very delicate holding of the cake |

| - No moving filter elements | - No sticking to the water |

| | | |

| No residual |

| - No residual filtration | |

| | | - High water consumption when washing |

| | | - Problem maintaining filter media |

| | | |

| - Impossibility of changing wine quality | |

| | | - Very high price |

Precoat

This is an essential phase which conditions all subsequent filtration.Theobjectives of the precoat are

- :

- To ensure instant clarification

- To facilitate the debatizing of the filter cake

Realisation:

It can be done in one, two or even three parts depending on the objectives set and, above all, on the state of the product to be filtered.

Thebasic rules are

- :

- In all cases, the adjuvant, deposited directly on the substrate, must have a permeability greater than or equal to 1 darcie.

- Never use fine kieselguhr (pink diatomaceous earth) directly, as it is difficult to attach and some of its very fine particles could pass through the support during filtration.

- Use a clear product (water or already filtered wine) to avoid clogging too quickly and to ensure a good cycle length.

- The flow rate through the filter should always be as high as possible (1.5 to 2 times the filtration flow rate) to ensure that the additive is evenly distributed over all the plates.

- Generally speaking, the minimum quantity of filtering agent for the precoat should be 1 kg/m² (up to 2 kg/m² may be used).

- In the case of a precoat in several parts, avoid mixing the filtering agents. In addition, never place a high-permeability diatomaceous earth after a finer diatomaceous earth, as this will form a layer of icing inside the cake, leading to rapid, totally irreversible clogging.

- When filling the filter, leave the air vent open to prevent degradation of the filter cake, as the CO2 will interfere with the installation of the precoat.

- Under normal conditions, when the precoat is in place, the pressure drop is 0.3 to 0.5 bar.

Filtration additive

Filtration by alluviation requires the choice of one or more filtering additives adapted to the type of product to be clarified and to the objectives sought.Generally speaking, diatoms can be classified into 3 categories

- :

- Rapid or roughing diatoms Destined

- .

- Medium or clarifying These

- .

- Fine or finishing These

Note: perlites are categorised in the same way. Cellulose and by-products are only technical complements to the constitution of the precoat.

Note: perlites are categorised in the same way. Cellulose and by-products are only technical complements to the pre-layer.

Alluvium

Throughout

the filtration process, the regular addition of kieselguhr makes it possible to

- the quantity of particles to be filtered (charge)

The type and quantity of additive to be used must be chosen to ensure a slow, steady increase in pressure at the filter inlet. Experience makes these choices easier

- :

- increase the filtration cycles by delaying clogging

- reduce the differential pressure

- maintain the porosity of the cake as high as possible

- :

- Alluviation is carried out with the admixture used to form the last part of the precoat. Never use a diatomaceous earth that is "faster" than the one used to finish the precoat. A layer of icing will form on the inside of the cake, as in the case of a poor precoat.

- The optimum dosage depends on:

- the quantity of particles to be filtered (charge)

The type and quantity of additive to be used must be chosen to ensure a slow, steady increase in pressure at the filter inlet. Experience makes these choices easier

Horizontal

loaded with filter cake

We can obtain as a general rule :

| Type of wines|| | Average alluvial doses |

|---|---|

| New wines |

| Early filtration on products with a high load and very poor filterability | 150 to 170 g/hl |

| Raw wines |

| Unfined, racked | 110 to 130 g/hl |

| Fined wines | 80 to 100 g/hl|| |

| Pre-filtered wines + fining | 60 to 80 g/hl|| |

Filtration line

In this type of filtration, the filtering medium is the filter itself, in a continuous process.The filtration cycle consists of 2 stages:

Constitution of

the precoat (sizing)

|On

the filtering support, a filtration layer is constituted with a filtration aid which can be kieselguhr (diatomaceous earth), perlite, or even various fibres (cellulose, polyethylene, etc.)

|

||

Alluvionage

A

mixture of wine to be filtered and filter aid is added throughout the filtration process. This superimposes a series of filter layers comprising the filter aid and the retained impurities

|

||

Residual

filtration

Horizontal plate filters are equipped with residual filtration devices, the aim of which is to clarify and evacuate all the wine contained in the filter at the end of the cycle.

There are 2 types of system

- :

- The external auxiliary filter

- The plates integrated into the base of the filtering "pack"

Removing the filter cake at the end of filtration or after clogging.

Depending

on the type of filter, the cake is removed as follows

In the

- :

- by cleaning with water for models with vertical plates

- in paste form or not for models with horizontal plates

latter case, 2 configurations are possible

- :

- automatic by moving the filter elements

- manual by tilting the plates

|

||

Cleaning

Washing is carried out using water pressurised by the general supply pump. The appliance can be fitted with an internal washing ramp, which may or may not be mobile.

The

Washing is carried out using water pressurised by the general supply pump. The appliance can be fitted with an internal washing ramp, which may or may not be mobile.

cleaning discharge is pasty.

Note: Periodic chemical cleaning is necessary to prevent clogging and scaling of the filter elements

|

||

Choosing the right equipment

Defining the most suitable filtering surface for a given production unit requires a whole series of technical, economic and practical parameters to be taken into account. To do this, a case-by-case study should be carried out with a professional.Resolving malfunctions

Pressure ΔP increases too quickly- The additive is unsuitable

- - Use a less fine diatomaceous earth

- The alluvium is insufficient

- - Increase the concentration of additive in the mixing tank

- Increase the alluvium flow rate

- The flow rate of the main pump is too high

- -

- Reduce feed pump flow

- - Increase bypass volume

- Admixture unsuitable

- -

- Use a finer diatomaceous earth

- Alluviation is greater than required

- - Reduce the concentration of adjuvant

- - Reduce the flow rate of alluviation

- The flow rate of the main pump is too low

- - Increase the flow rate of the feed

- Alluviation adjuvant is finer than that of the last precoat,

- resulting in

- clogging The concentration of solids increases (e.g. at the bottom of the vat)

- The

- Reduce the impurity load by dilution: Some of the filtered wine is returned to the main pump suction via the bypass.

- This is often necessary when filtering new wines.

- Reduce the inlet flow rate to the bell.

- Increase alluviation by accelerating the flow rate of the dosing pump.

- Increase the concentration of adjuvant in the alluviation tank.

The

- Activate the air vent frequently, especially in the case of young wines with a high CO2 content

- Avoid pressure surges by handling the valves carefully.