Grape and wine transfer equipment

Grape and wine transfer equipment includes mobile or fixed equipment for transporting grapes, pomace and stems.

Mechanical conveyors preserve the condition of the grapes better than pumps, but are bulkier and more difficult to clean. Transfer pumps can be divided into 2 groups: positive displacement pumps, suitable for low flow rates and high pressures, and rotary displacement pumps, with centrifugal or self-priming models.

Mechanical conveyors preserve the condition of the grapes better than pumps, but are bulkier and more difficult to clean. Transfer pumps can be divided into 2 groups: positive displacement pumps, suitable for low flow rates and high pressures, and rotary displacement pumps, with centrifugal or self-priming models.

Grape and wine transfer equipment

Grape and wine transfer equipment is used to move fresh, drained or fermented grapes, marc and stems to the winery. This equipment can be mobile, on wheels or stationary.

Mechanical conveyors generally take better care of the physical state of the harvest than pumps, but they have more limited flow rates, take up more space and are more tedious to clean.

Transfer pumps fall into two categories:

- Volumetric pumps: wine pumps and grape harvest pumps

- Rotodynamic pumps: wine pumps

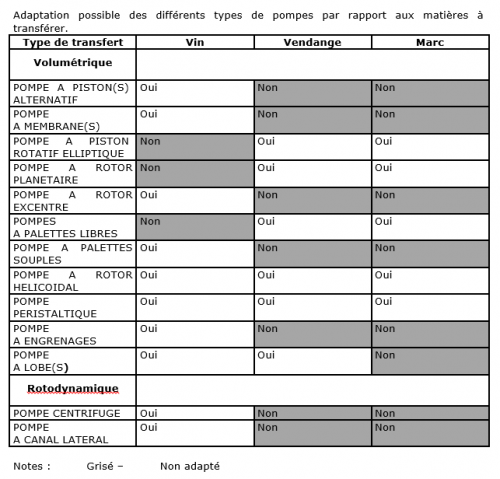

Characteristics of use of transfer pumps in relation to the materials to be transferred (Notes: Shaded - Not suitable)

Purpose of positive displacement pumps

Positive displacement pumps consist of a moving element that moves within a perfectly fitting fixed body.The fluid is displaced by movement between the suction port and the discharge port due to the decrease in pressure upstream.

Main features :

- low flow rate

- good efficiency

- self-priming

A general distinction is made between :

- Reciprocating positive-displacement pumps: the moving part moves in an alternating motion.

- 1-shaft rotary positive displacement pumps: these pumps are made up of a moving part that rotates around an axis, which rotates in the pump casing and creates the movement of the pumped liquid by displacing a volume from the suction to the discharge side.

- Rotary positive displacement pumps with 2 shafts: known as double impellers.

Positive displacement pumps are generally self-priming. As soon as they are started up, they cause a drop in pressure upstream, allowing the liquid to be drawn in. It is nevertheless necessary to examine the manufacturer's instructions.

Positive displacement pumps allow much higher total head than centrifugal pumps. The discharge pressure is therefore higher. The flow rate, on the other hand, is generally lower, but is virtually unaffected by the characteristics of the network. Efficiency is often around 90%, except in the case of internal leaks.

If the discharge pipe is blocked, a positive displacement pump should be stopped immediately in this situation to avoid the risk of a very large increase in pressure in the pump, which could lead to serious damage.

If valves in the discharge circuit can be closed, a safety device should be installed at the pump outlet: a bypass fitted with a safety valve and connected to the suction tank is a good solution.

The flow rate is adjusted by varying the speed of rotation of the rotor for rotary pumps and the frequency or stroke of the piston for reciprocating pumps.

Purpose of rotodynamic pumps

Rotodynamic pumps consist of :- An impeller rotating on its own axis

- A diffuser in the impeller axis

There are two categories of rotodynamic pumps:

- Non-self-priming centrifugal rotodynamic pumps

- Self-priming central channel rotodynamic pumps

Purpose of mechanical conveyors

There are several types of mechanical conveyors (vibrating table, lift, crusher, decanter, crusher belt, decanter belt, lift belt, grasshopper, conveyor belt and haul-off) used to transport the grapes or pomace: belt conveyors, Archimedes screw conveyors, chain and paddle conveyors and vibrating plate conveyors.Experiment

See the list of experimentsSee more - Recommendation for phthalate risk management in cellars - 2021

- Wine transfer: key points and control measures - 2018

- Evaluation and impact of oxygen levels in packaging - 2018

- Harvest: preparing the cellar - 2016

- Impact of oxygen levels on conditioning - 2016

- Pipe scraping: functionality and environmental benefits - 2012

- Filling vats by gravity: an effective technique for optimising wine quality - 2010

- [TEST EQUIPMENT] Comparative test bench, wine pumps - 2005