Vine shoot puller

The mechanisation of wood descent in viticulture helps to reduce production costs, thanks to a range of machines designed to pull shoots sideways or upwards, with some incorporating a shredder. The hydraulic requirements are high to ensure that all the components work properly.

The main brands, such as Clemens, Ero and Provitis, offer a variety of solutions tailored to the specific needs of each vineyard.

The main brands, such as Clemens, Ero and Provitis, offer a variety of solutions tailored to the specific needs of each vineyard.

Work objective

The mechanisation of the descent of the wood is an interesting option in the context of optimising production costs. There are a number of different approaches to this, including pulling the wood sideways (similar to manual wood pulling) or upwards.

Some machines crush the shoots simultaneously. The hydraulic requirements are fairly high, since the various parts are driven by hydraulic motors.

Ero sets itself apart from other manufacturers by offering a shoot-pulling machine that requires all the wires to be unhooked as it passes through.

Wood-pulling machine

Kobold - Clemens

Wood-pulling machine

Viteco - ERO

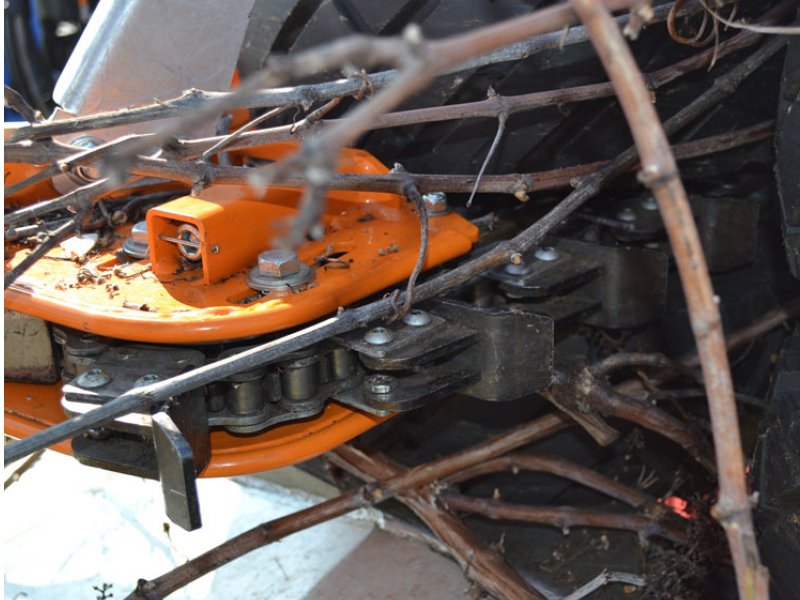

Components of the wood-pulling machine

The extractor

Vine shoot extraction module

These are the extractors that replace the manual effort of pulling the wood.

These are close-together rollers that grab the shoots and pull them out of the trellis, upwards on the ERO and CLEMENS machines and sideways on the PROVITIS machine. In the case of the PROVITIS machine, there is an additional specificity, with the presence of a horizontal star disc that pushes the shoots sideways towards the rollers.

These are close-together rollers that grab the shoots and pull them out of the trellis, upwards on the ERO and CLEMENS machines and sideways on the PROVITIS machine. In the case of the PROVITIS machine, there is an additional specificity, with the presence of a horizontal star disc that pushes the shoots sideways towards the rollers.

The shredder

The purpose of the shredder is to reduce the vine shoots to fractions that can be degraded on the ground.It is standard on the VITECO ERO machine, optional on the CLEMENS KOBOLD machine, and not present on the PROVITIS machine. It can be mounted behind the tractor to complete the work.

The mast

The purpose of the mast is to support the machine and position it for work.The mast supporting the machine must be equipped with tilting and opening functions for optimum positioning in relation to the trellising.

The hydraulic control unit

The machine's position controls and extractors require a lot of hydraulic power. The central hydraulic unit provides the necessary flow: from 30 to 60 L/min with or without the shredder.Adjusting and using the wood-pulling machine

The wood-pulling machines on the market differ in design. They all have the same function but different settings and uses.Ero offers a machine equipped with two jaws that close on the wood and wires. As it moves forward, it unhooks the lifting and upper wires, and a system of augers and wheels transports the wood to the shredder, which throws it back to the ground in small fragments.

To use this machine, the trellising must be prepared (the upper wire must be detachable).

Clemens (Kobold) offers a machine which, like Ero, ejects the shoots upwards. It too is equipped with a vine shoot crusher.

Unlike the Ero, however, it does not require any adjustment to the trellising. Two wheels drive the shoots towards the crusher, and a wire guide holds the upper wire under the machine.

Provitis has developed a wood-pulling machine that is completely different from the previous two. The wood is pulled out sideways, similar to the work done manually. A plastic disc carries the shoots to the side, where they are caught by rubber wheels and thrown to the ground. The machine is not equipped with an integrated shredder, but can be combined with a shredder attached behind the tractor to complete the work.

The machine is positioned in the row by a set of jacks. This makes it possible to adjust the height, lateral offset and slope (Clemens and Ero).

All these machines require high oil flow rates (30 to 60 litres/min).