Cartridge filter

Cartridge filtration stabilises the wine microbiologically before bottling. The cartridges are chosen according to their retention threshold in microns, with larger pores for clarification (greater than 1 µm) and smaller pores for sterilisation (less than 1 µm). The cartridges are inserted vertically and sealed with gaskets. The system includes pre-filtration and sterilisation housings, as well as a variable flow pump. Clogging and integrity tests guarantee effective filtration, with regular regeneration of the cartridges to extend their life.

Cartridge filter

Cartridge filtration is a microbial stabilisation process that takes place just before bottling.Main components

The cartridges

Their height is often given in inches (10 inches = 254 mm).They are available in 10, 20, 30 or 40 inch sizes.

Cartridges are characterised by their retention threshold, given in µm.

The choice of cartridges depends on the application.

As a guide:

Pore diameter > 1 µm: clarifying filtration

Pore diameter <1 µm: sterilising filtration

Cartridge filter

Cartridges

The table below shows the filtration thresholds required to retain yeast and bacteria.

| Pore Ø | Result |

|---|---|

| > 1 µm |

Removal of particles Reduction in germ count |

| 1 µm | Elimination of a large proportion of yeasts, but not bacteria |

| 0.65 µm | Total elimination of yeasts and some bacteria |

| 0.45 µm | Total elimination of yeast and bacteria. |

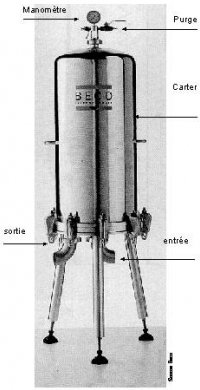

The housing

This is adapted to the height and number of cartridges.Several housings can be fitted in series, forming a filtration paddle.

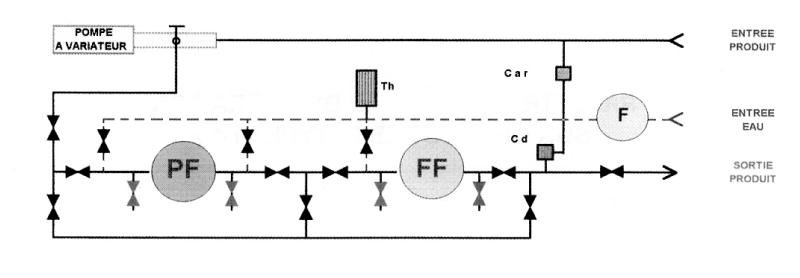

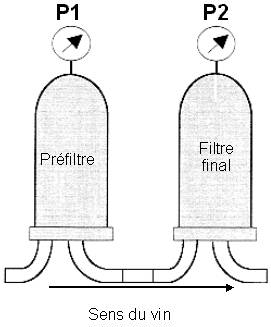

A pallet generally comprises the following elements (Figure 1):

- one or more wine housings (usually two), the first of which, fitted with a pre-filtration cartridge, protects a sterilisation membrane placed in the second one

- a water filtration housing for rinsing, sterilising and regenerating the cartridges

- a by-pass circuit with discharge valve and non-return valve to prevent over-pressurisation of the cartridges and allow the bottling machine to be shut down without damage

Schematic diagram of a filtration paddle

| F: Water filter | Th: Thermometer |

| PF: Pre-filter | Car : By-pass non-return valve |

| FF: Final filter | Cd: By-pass discharge valve |

Some manufacturers now offer automated pallets for cleaning and integrity testing.

The pump

It must have a variable flow rate, not give a jolt, not emulsify the wine, and be fitted with a safety valve so as not to exceed the maximum authorised pressure (volumetric pump type, known as a pigtail or helical rotor pump).

Stages of filtration

Preparing wines for filtration

To avoid rapid clogging, the wine must be carefully pre-filtered.

To check the effectiveness of pre-filtration, three measurements are possible: the clogging index (CI), the modified clogging index (MCI) and filterability (Vmax).

Equipment required :

- a 0.65 µm membrane 25 mm in diameter

- a 500 ml test tube

- a stopwatch

- a manometer

To check the effectiveness of pre-filtration, three measurements are possible: the clogging index (CI), the modified clogging index (MCI) and filterability (Vmax).

Equipment required :

- a 0.65 µm membrane 25 mm in diameter

- a 500 ml test tube

- a stopwatch

- a manometer

- Clogging index (C.I.) test

Measure the passage times (in 100ths of minutes) of the first 200 ml of wine and 400 ml.

I.C. = T400 - 2T200

Membrane filtration can be carried out under good conditions if the wine has a C.I. ≤20.

Membrane filtration can be carried out under good conditions if the wine has a C.I. ≤20.

- Modified Clogging Index (MCI) test

M.C.I. = ((T400-T300) - (T300-T200)) * 2

Membrane filtration can be carried out under good conditions if the wine has an I.C.M. ≤10.

Membrane filtration can be carried out under good conditions if the wine has an I.C.M. ≤10.

- Vmax filterability test (estimation of maximum volume at clogging)

Record the volumes filtered at 2 minutes and 5 minutes at a constant pressure of 1 bar.

Calculate the theoretical volume of the cartridge to be used

If Vmax ≤ 4000: the volume filtered will be less than the theoretical volume (rapid clogging).

If Vmax ≥ 5000: the volume filtered will be greater than the theoretical volume (slow clogging).

If Vmax ≥ 5000: the volume filtered will be greater than the theoretical volume (slow clogging).

Determining the number of cartridges to use

The number of cartridges required is determined by the constant flow rate of the filler.The average flow rate of a cartridge is 3 to 5 hl/h per 10-inch length.

Example (for an 8 to 10 hour day):

A filter equipped with 30-inch cartridges and a bottling machine working at a rate of 10,000 bottles/hour.

The output of the bottling machine is 10,000 x 0.75/100 = 75 hlL/hour

The minimum number of cartridges to be installed is 75 / (5 x 3) = 5

Setting up the system

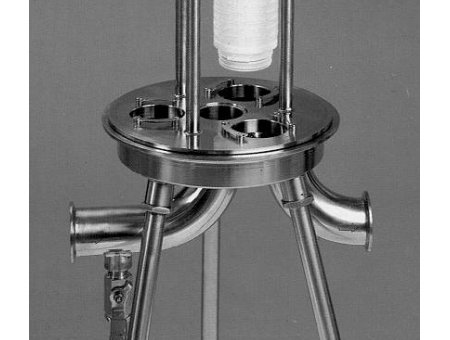

- Insert the cartridges vertically onto the housing support plate

- Tightness is ensured, usually by 2 O-rings and 2 bayonets

- Replace the cover

- Connect the filter to the pump

- Open the bleed taps

Rinsing and sterilisation

- Rinse the cartridges with filtered water for the time recommended by the manufacturer.

- For germ-free filtration, sterilise the cartridges with filtered water on 1 mm media, in the direction of filtration, using low pressure, steam or hot water (approx. 90°C).

It is advisable, if possible, to sterilise in-line, from the filter to the filler (including the by-pass circuits).

The 90°C should be measured at the filler nozzles.

Integrity test or pressure maintenance

Some cartridges allow their quality to be checked by means of an integrity test, which provides information about the regularity of pore diameter and the condition of the seals.Procedure: (consult manufacturers' manuals)

- Fill the sump with cold water

- Open the drain valves until all the water has been removed

- Close the inlet valve and leave the outlet valve open

- Pressurise the crankcase to the recommended pressure using air or nitrogen

Notes: Checking the quality of the filter, in working order, is a very valuable feature of cartridge filters.

The integrity test can now be automated on new filtration pallets.

Monitor the pressure on the manometer. It is recommended to work at the lowest possible differential pressures and to regenerate the cartridges before reaching 3 bars of differential pressure for a longer service life.

Monitoring filtration

Using pressure gauge readings in a filtration pallet

Pre-filter clogging

P1 - P2 ≥ 3 bars

Clogging in the final filter

P2 ≥ 3 bars

P1 - P2 ≥ 3 bars

Clogging in the final filter

P2 ≥ 3 bars

Examples:

P1 = 6 bars and P2 = 3 bars

Pre-filter: P1 - P2 = 3 bars

Final filter: P2 = 3 bars

The 2 stages are clogged.

P1 = 3 bars and P2 = 3 bars

Pre-filter : P1 - P2 = 0 bar

Final filter: P2 = 3 bars

Only the final filter is clogged

P1 = 4 bars and P2 = 1 bar

Pre-filter : P1 - P2 = 3 bar

Final filter: P2 = 1 bar

Only the prefilter is clogged

P1 = 6 bars and P2 = 3 bars

Pre-filter: P1 - P2 = 3 bars

Final filter: P2 = 3 bars

The 2 stages are clogged.

P1 = 3 bars and P2 = 3 bars

Pre-filter : P1 - P2 = 0 bar

Final filter: P2 = 3 bars

Only the final filter is clogged

P1 = 4 bars and P2 = 1 bar

Pre-filter : P1 - P2 = 3 bar

Final filter: P2 = 1 bar

Only the prefilter is clogged

Regeneration

To be carried out every evening after draining the wine or when the pressure build-up indicates the start of clogging, following the procedures recommended by the manufacturer:Regeneration with cold water followed by regeneration with hot water at 50°C, in the direction of filtration (co-current) or against the current (in this case, respect the recommended reverse pressure). Pre-filter: co-current or counter-current; final filter: co-current.

Recommended regeneration flow rates (necessary and sufficient):

- co-current: 5 hl/h for 20 minutes for a 30-inch cartridge

- counter-current: flow rates indicated by the manufacturers depending on the type of membrane

Note: It is essential to clean each housing individually.

Storage of equipment and cartridges

Stopped for less than 72 hours

The filter must be sterilised and the water removed by blowing with air or nitrogen.

Out of service for more than 72 hours

The filter can either be stored in a solution recommended by the supplier, or sterilised, purged, dismantled, dried and stored in a clean, dry place (note that drying is not authorised for all membranes as it can lead to a loss of integrity).

The filter must be sterilised and the water removed by blowing with air or nitrogen.

Out of service for more than 72 hours

The filter can either be stored in a solution recommended by the supplier, or sterilised, purged, dismantled, dried and stored in a clean, dry place (note that drying is not authorised for all membranes as it can lead to a loss of integrity).