Heat pump - Chiller/heater

The cooler-heater, also known as a thermo-frigopump in oenology, is a versatile device that can be used to heat or cool must or wine directly. It works on the heat pump principle, using a closed circuit with an evaporator, compressor, condenser and expansion valve to transfer heat or cold as required. This appliance is particularly effective for operations such as low-temperature must cooling or tartaric stabilisation. However, it is ill-suited to precise, regular control of fermentation or maceration temperatures and is not suitable for high temperatures (above 35-40°C). In oenology, its intensive use can lead to risks such as excessive stirring of the must, which can affect the quality of the wine.

The wine cooler-heater (heat pump or PAC) is used to treat must or wine directly. This multi-purpose device (cooling and heating) is well suited to cooling must or wine at low temperatures (from cold settling to tartaric stabilisation).

Although it can be used to limit temperatures that are too high or too low, it is ill-suited to correct and regular control of alcoholic and malolactic fermentation temperatures, as well as regular maintenance of stabulation or maceration temperatures, and is completely unsuitable for heating musts to temperatures above 35-40°C.

Although it can be used to limit temperatures that are too high or too low, it is ill-suited to correct and regular control of alcoholic and malolactic fermentation temperatures, as well as regular maintenance of stabulation or maceration temperatures, and is completely unsuitable for heating musts to temperatures above 35-40°C.

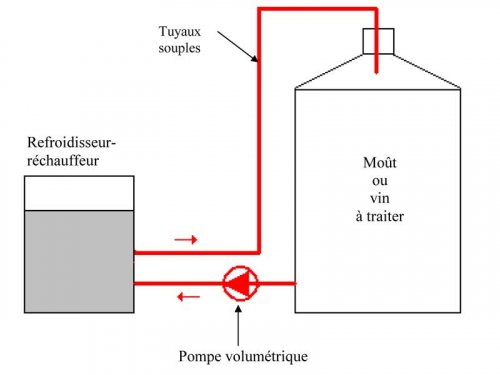

Wine cooler-heater

Intensive use of this system also means that the musts or wines are stirred a great deal, with all the resulting oenological risks (uncontrolled aeration, trituration by pumps, etc.).

Technical presentation

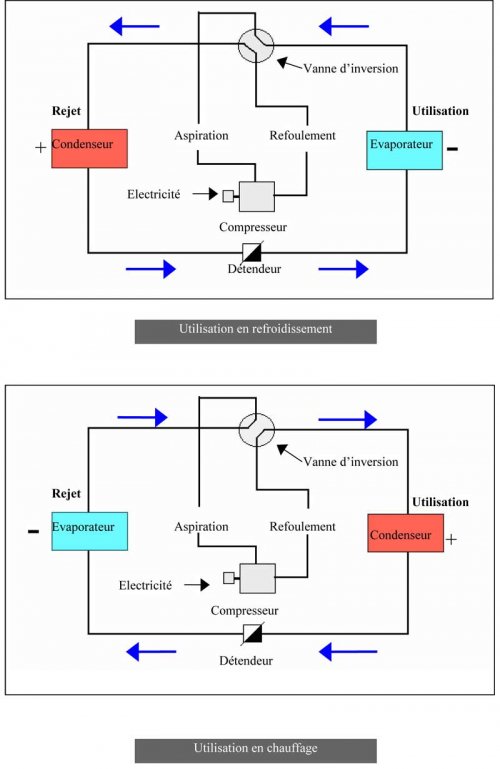

Chiller-heaters (or heat pumps or PACs) - like refrigeration units - have a closed circuit comprising the following components: evaporator - compressor - condenser - expansion valve.

A refrigerant circulates in this circuit. This liquefied gas evaporates in an evaporator, absorbing heat (cold source). Recompressed by a compressor, it condenses in a condenser, releasing heat (hot source). If the product (must, wine) is brought into contact with the hot source (condenser), the appliance operates as a heat pump. If the product is brought into contact with the cold source (evaporator), the appliance operates as a refrigeration unit.

A refrigerant circulates in this circuit. This liquefied gas evaporates in an evaporator, absorbing heat (cold source). Recompressed by a compressor, it condenses in a condenser, releasing heat (hot source). If the product (must, wine) is brought into contact with the hot source (condenser), the appliance operates as a heat pump. If the product is brought into contact with the cold source (evaporator), the appliance operates as a refrigeration unit.

Heat pump

In the wine industry, these units can either heat or cool the must or wine: they are reversible.

The refrigeration cycle is then reversed by means of a 4-way valve that switches the role of the heat exchangers with the two sources. The evaporator (removing cold) becomes the condenser (removing heat) and vice versa.

Operating diagram of a chiller-reheater

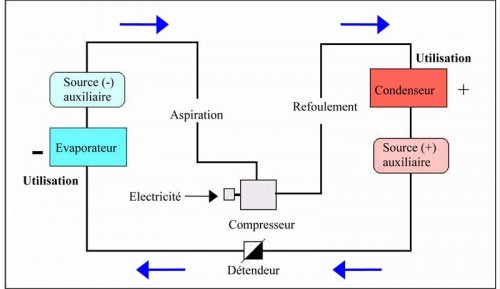

Some equipment simultaneously heats and cools: these are heat pumps. Each of the two modes of operation requires the two opposing sources of energy to be controlled so that the balance of energy is always maintained, i.e. :

Heat pump operating diagram

Heating capacity = Cooling capacity + Power input

When this balance is not achieved - which corresponds to the majority of cases - it is necessary to evacuate the surplus. This is unrealistic in wine-making. This is why this type of equipment is rarely used in the wine industry.

Heat pump operating diagram

Main components

The evaporator

Any liquid that evaporates absorbs heat. As the refrigerant circulates through the evaporator, it changes from a liquid to a gas, absorbing heat from the product being treated and cooling it. The evaporator is therefore a heat exchanger in which :- on one side, the refrigerant,

- on the other, the fluid to be cooled (wine, must).

The compressor

Driven by an electric motor, the compressor draws in the fluid vaporised in the evaporator and compresses it, increasing its pressure and raising its temperature. The fluid is expelled in a gaseous state at high temperature and high pressure, making it condensable.The compressor consumes electrical energy through its drive motor.

The condenser

In this heat exchanger, the hot refrigerant gas transfers its heat to the external fluid (air or water), which is at a lower temperature. This heat transfer results in the condensation of the gas.The condenser is therefore a heat exchanger in which :

- on one side, the refrigerant,

- on the other, the fluid to be heated (water or air).

The expansion valve

As it passes through the expansion valve, the pressure of the refrigerant decreases until it reaches the pressure of the evaporator, to facilitate its vaporisation. This completes the cycle.* In a chiller-heater, the evaporator acts as a condenser during cycle inversion.

Installing a wine cooler-heater is extremely simple, as these units are connected directly to a volumetric wine pump (vane, piston or "pigtail") using the same fittings (usually macon thread) used in wine cellars.

A temperature sensor placed in the pipe or in the vat is used to monitor the temperature, and an electronic controller is used to stop cooling or heating according to a set temperature set by the user.

In this type of equipment, it is the evaporator that is connected to the appliance via flexible pipes. The evaporator acts as an internal heat exchanger. The must or wine is cooled or heated without being displaced. A temperature sensor immersed in the vat and connected to a regulator stops cooling or heating at a set temperature set by the user. This type of appliance, generally of low to medium power, is used exclusively for treating liquid phases (whites, rosés).

A temperature sensor placed in the pipe or in the vat is used to monitor the temperature, and an electronic controller is used to stop cooling or heating according to a set temperature set by the user.

In this type of equipment, it is the evaporator that is connected to the appliance via flexible pipes. The evaporator acts as an internal heat exchanger. The must or wine is cooled or heated without being displaced. A temperature sensor immersed in the vat and connected to a regulator stops cooling or heating at a set temperature set by the user. This type of appliance, generally of low to medium power, is used exclusively for treating liquid phases (whites, rosés).

Choice of equipment

The cooler-heater is particularly useful for heat-treating must when you want to reach a given temperature very quickly and evenly.Operations requiring this type of equipment include heating or cooling must with medium to large temperature variations (cooling white must, hot final maceration at medium temperature, cooling for tartaric stabilisation, etc.).

It can also be used in small wineries to compensate for temperature variations during alcoholic or malolactic fermentation. In this case, intensive use will result in a lot of stirring of the musts and wines, except in the case of a mobile heat exchanger (see above).

The thermal power required for the operation to be treated or for the winery as a whole (see chapter on "Assessing thermal requirements") will determine the power of the appliance to be installed.

The power required by a heat pump is given by the following formula:

Qequipment = Qnecessary X 24 / TP use

where

Qnecessary: Power calculated during the heat balance (W or frig/h or kcal/h)

TP use: Duration of daily use of the appliance *

* It is not recommended to leave this appliance running without supervision (risk of pipe rupture, overheating or overcooling).

where

Qnecessary: Power calculated during the heat balance (W or frig/h or kcal/h)

TP use: Duration of daily use of the appliance *

Example of the equipment in a white wine-making vat (see chapter "Assessment of thermal requirements") using a chiller-heater:

Qnecessary = 52000 frig/h TP use = 15 h

Qequipment= 52000*24/15 = 83200 frig/h* (96.8 kW)

*For the temperature conditions of each operation (air: 25 °C, must at 15 °C)

Qnecessary = 52000 frig/h TP use = 15 h

Qequipment= 52000*24/15 = 83200 frig/h* (96.8 kW)

*For the temperature conditions of each operation (air: 25 °C, must at 15 °C)

Each appliance has its own characteristics, but the user or specifier should bear in mind several general rules of great practical interest:

- The cooling capacity of a chiller-heater increases as the evaporation temperature rises and the condensation temperature falls.

- The heat output of a chiller-heater decreases as the condenser temperature rises and the evaporator temperature falls.

- Most cooler-heaters can theoretically reach temperatures of -5°C, which are necessary for wine stabilisation, but in practice they need to be designed to effectively prevent icing and scaling (e.g. "scraped surface exchangers").

- Current wine cooler-heaters can hardly exceed maximum temperatures of 35 to 40°C with acceptable power.

- The practical heat output of a wine cooler-heater takes into account the characteristics of the compressor, the working conditions (ambient temperature and temperature of the wine to be treated), the quality of the exchanges at the condenser and evaporator and the ancillary equipment (fans, pumps, etc.).

- The desired must or wine temperature

- The outside air temperature

- The fluid used (R22, R407, R134a, ammonia)

Malfunctions: Questions and Answers

Chillers and heaters are generally fitted with indicators or lights to monitor their operation.Discharge pressure

(This is analysed by a pressure switch, which monitors the efficiency of the condensation process. Any loss of efficiency resulting in a rise in pressure is due to :- Dirty tubes in the condenser

- A reduction in the flow of air (fan failure) or water to the condenser.

The pressure at which the refrigerant evaporates (B.P. or L.P. indicator or sight glass)

This is controlled by a B.P. pressure switch. Too low a pressure is due to :- A lack of refrigerant

- Faulty expansion valve

- A blocked dehydrator

- A defective capacity reduction device.

The temperature of the fluid leaving the evaporator (temperature indicator or sight glass)

This is measured by a low-temperature thermostat. The main reasons for a low wine temperature are as follows:- Reduced wine flow (pump failure)

- A set point that is too low.

Effective compressor pressure

This is measured by an oil pressure switch which gives the difference between the oil pressure in the lubrication circuit and the suction crankcase pressure. Any drop in oil pressure may be caused by :- Lack of oil

- A faulty oil pump

- Destroyed oil resistance promoting condensation of the coolant in the oil.