Thermal treatment tank

A thermal treatment tank is used to cool or heat the must or wine, ensuring precise temperature control. It uses a reversible thermodynamic cycle with a refrigerant that circulates between an evaporator and a condenser. The evaporator cools the liquid by absorbing heat, while the condenser heats it by releasing heat. This system, equipped with an agitator to homogenise the temperature, is effective for small quantities and enables tartaric stabilisation, fermentation or bottling at controlled temperatures.

The Thermal treatment tank can also be used to treat must or wine directly . This multi-purpose tank (cooling and heating) is well suited to cooling musts or wines at low temperatures (from cold settling to tartaric stabilisation).

It is only suitable for small vats (< 5 vats) for controlling fermentation or stabulation temperatures. Beyond that point, the amount of liquid handled becomes too great to ensure correct temperature control. This appliance avoids the need for pump stirring by homogenising the liquid with a slow-speed paddle stirrer.

It is only suitable for small vats (< 5 vats) for controlling fermentation or stabulation temperatures. Beyond that point, the amount of liquid handled becomes too great to ensure correct temperature control. This appliance avoids the need for pump stirring by homogenising the liquid with a slow-speed paddle stirrer.

Thermal treatment tank

Technical description

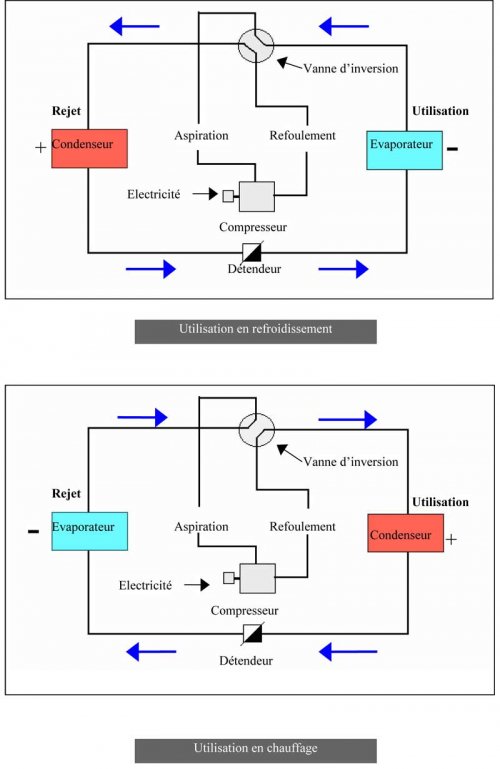

Figure 1: Diagram of a thermal treatment tank

Thermal treatment tanks, like refrigeration units, have a closed circuit comprising the following components:

evaporator - compressor - condenser - expansion valve.

A refrigerant circulates in this circuit. This liquefied gas evaporates in an evaporator in the form of a double jacket tank, absorbing heat (cold source). Recompressed by a compressor, it condenses in a condenser , releasing heat (hot source).

If the product (must, wine) is brought into contact with the hot source (condenser), the appliance operates as a thermal pump. If the product comes into contact with the cold source (evaporator), the appliance operates as a refrigeration unit.

In the wine industry, these units can either heat or cool must or wine : they are reversible.

The refrigeration cycle is then reversed by means of a 4-way valve that switches the role of the thermal exchangers with the two sources. The evaporator (evacuating cold) becomes a condenser (evacuating heat) and vice versa (see Figure 1).

evaporator - compressor - condenser - expansion valve.

A refrigerant circulates in this circuit. This liquefied gas evaporates in an evaporator in the form of a double jacket tank, absorbing heat (cold source). Recompressed by a compressor, it condenses in a condenser , releasing heat (hot source).

If the product (must, wine) is brought into contact with the hot source (condenser), the appliance operates as a thermal pump. If the product comes into contact with the cold source (evaporator), the appliance operates as a refrigeration unit.

In the wine industry, these units can either heat or cool must or wine : they are reversible.

The refrigeration cycle is then reversed by means of a 4-way valve that switches the role of the thermal exchangers with the two sources. The evaporator (evacuating cold) becomes a condenser (evacuating heat) and vice versa (see Figure 1).

Main components

The evaporator

Any liquid that evaporates absorbs heat. As the refrigerant circulates through the evaporator, it changes from a liquid to a gas, absorbing heat from the product being treated and cooling it. The evaporator is therefore a thermal exchanger in which :- on one side, the refrigerant,

- on the other, the fluid to be cooled (wine, must).

Note : The inside of the evaporator, which is actually the tank shell, should be made of 304 or 316 L stainless steel for use directly on the must or wine.

The compressor

Driven by an electric motor, it draws in the fluid vaporised in the evaporator and compresses it, increasing its pressure and raising its temperature. The fluid is expelled in a gaseous state at high temperature and high pressure, making it condensable.The compressor consumes electrical energy through its drive motor.

The condenser

In this thermal exchanger, the hot refrigerant gas transfers its heat to the external fluid (air or water), which is at a lower temperature. This thermal transfer results in the condensation of the gas.The condenser is therefore a thermal exchanger in which :

- on one side, the refrigerant,

- on the other, the fluid to be heated (water or air).

The expansion valve

As it passes through the expansion valve, the pressure of the refrigerant decreases until it reaches the pressure of the evaporator, to facilitate its vaporisation. This completes the cycle.Installation

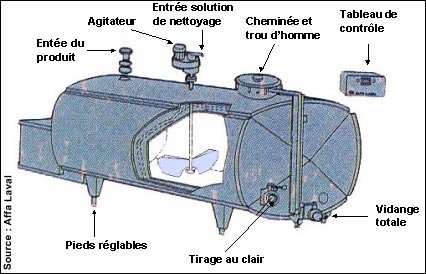

Setting up a thermal treatment tank is extremely simple , as these tanks are designed to be used in the same way as traditional wine tanks.

A temperature sensor placed in the tank monitors the temperature and an electronic controller controls cooling or heating according to a set temperature set by the user.

A stirrer with large blades can be started up at a very slow speed to homogenise the temperature, improve the tank's heat exchange coefficient and prevent freezing during treatment at very low temperatures.

Some models also incorporate a washing system using a diffuser or the agitator shaft, as well as a connection for inerting the tank.

The tank geometry can be cylindrical or semi-cylindrical, horizontal or vertical.

A temperature sensor placed in the tank monitors the temperature and an electronic controller controls cooling or heating according to a set temperature set by the user.

A stirrer with large blades can be started up at a very slow speed to homogenise the temperature, improve the tank's heat exchange coefficient and prevent freezing during treatment at very low temperatures.

Some models also incorporate a washing system using a diffuser or the agitator shaft, as well as a connection for inerting the tank.

The tank geometry can be cylindrical or semi-cylindrical, horizontal or vertical.

Diagram of a heat treatment tank

Choice of equipment

This type of equipment is particularly useful for thermal treatment of must or wine when you want to reach a given temperature very quickly, gently (without transferring wine) and evenly.This type of equipment is used for heating or cooling must with small or large temperature variations (cooling white musts, cold liquid stabulation of musts, mutage of sweet white wines, tartaric stabilisation of wines, temperature-controlled bottling). It can also be used in small wineries to compensate for temperature variations during alcoholic or malolactic fermentation. In this case, intensive use means that the musts and wines to be treated need to be moved frequently.

The power of a thermal treatment tank must correspond to the thermal power calculated for the operation to be treated or for the winery as a whole.

Q appliance = Q required

where Qnecessary: Power calculated during the heat balance (W or frig/h or kcal/h)

where Qnecessary: Power calculated during the heat balance (W or frig/h or kcal/h)

Example of equipment of the white vinification vat room (see chapter "Assessment of heat requirements") using a thermal treatment tank:

Qnecessary = 52000 frig/h

Qequipment= 52000 frig/h* = 60.5 kW*

For the temperature conditions of the operation (air: 25 °C, must at 15 °C)

Qnecessary = 52000 frig/h

Qequipment= 52000 frig/h* = 60.5 kW*

For the temperature conditions of the operation (air: 25 °C, must at 15 °C)

Once the power of the appliance has been determined, it should be based on :

- The desired temperature of the must or wine

- The temperature of the outside air The fluid used (R22, R407, R134a, ammonia)

Malfunctions : Questions and answers

Thermal treatment tanks are generally fitted with indicators or lights to monitor their operation.Discharge pressure

(H.P. indicator or sight glass)This is analysed by a pressure switch which monitors the efficiency of the condensation process. Any loss of efficiency resulting in a rise in pressure is due to :

- Dirty tubes in the condenser

- A reduction in the flow of air (fan failure) or water to the condenser.

The pressure at which the refrigerant evaporates

(indicator or sight glass B.P. or L.P.)This is controlled by a B.P. pressure switch. Too low a pressure is due to :

- A lack of refrigerant

- Faulty expansion valve

- A blocked dehydrator

- A defective capacity reduction device.

The temperature of the fluid leaving the evaporator

(temperature indicator or sight glass)This is measured by a low-temperature thermostat. The main reasons for a low wine temperature are as follows:

- Reduced wine flow (pump failure)

- A set point that is too low.

Effective compressor pressure

This is measured by an oil pressure switch which gives the difference between the oil pressure in the lubrication circuit and the suction crankcase pressure. Any drop in oil pressure may be caused by :- Lack of oil

- A faulty oil pump

- Destroyed oil resistance promoting condensation of the coolant in the oil.