Heat exchanger

Internal and external heat exchangers are used in winemaking and maturing vats to control the temperature using a heat transfer fluid (water or glycol).

Internal heat exchangers are suitable for fermentation, but less so for demanding heat treatments. They must be installed without fittings in the vats to avoid leaks.

External heat exchangers, which are more powerful, are used for rapid, high-volume heat treatment (thermovinification, stabilisation). Their choice depends on the type of product and the temperatures to be reached, with various models available to suit specific needs.

Internal heat exchangers are suitable for fermentation, but less so for demanding heat treatments. They must be installed without fittings in the vats to avoid leaks.

External heat exchangers, which are more powerful, are used for rapid, high-volume heat treatment (thermovinification, stabilisation). Their choice depends on the type of product and the temperatures to be reached, with various models available to suit specific needs.

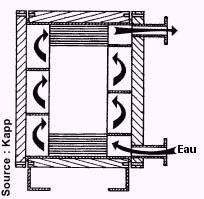

Internal heat exchangers

Internal" and "belt" heat exchangers combined with hot water production or production of chilled or glycoled water are the best solution for controlling alcoholic and malolactic fermentation temperatures, as well as for the stabulation or maceration phases. On the other hand, they are unsuitable, if at all, for heat treatments that require a great deal of power.It is not normally advisable to circulate glycoled water in internal heat exchangers, because of the risk of leakage into the vat. These risks can be very limited if the installation is properly tested at a pressure higher than the operating pressure (test pressure) and has no connections inside the tanks.

Equipped with automatic valves and temperature regulators, such an installation can control an entire vat room 24 hours a day without any stirring of the must or wine.

On some wine cooler-heaters (e.g. cryo-canners), the evaporator consists of a coil-type heat exchanger that can be immersed in a vat.

Technical presentation

Internal heat exchangers, belts or double envelopes are used to gradually heat or cool must, grapes or wine inside a tank (coils, drapes, radiators) or around a tank (belts, double envelopes).

These exchangers are supplied with chilled or glycoled water or hot water from the distribution networks described in the "Fluid distribution" chapter. We will not deal here with exchangers integrated into chillers or wine cooler-heaters, which operate on the same principle but with direct expansion.

These exchangers are supplied with chilled or glycoled water or hot water from the distribution networks described in the "Fluid distribution" chapter. We will not deal here with exchangers integrated into chillers or wine cooler-heaters, which operate on the same principle but with direct expansion.

Main components

For internal heat exchangers, the stainless steel grades used in the wine industry range from 304 and 304L to 316L. Surface treatments are 2B (cold-rolled glossy) or, to reduce scaling, 2RB (cold-rolled bright annealed) or with mechanical, chemical or electrochemical polishing.Welds

The quality of the welds, which are always present whatever the type of exchanger, must be impeccable. These welds must be airtight (TIG or other processes) and finished by grinding or polishing to make them easier to cleanSpecial case of the KREYER KTH heat exchanger

This extendable coil is fitted with a float that allows it to remain on the surface of the liquid and thus follow the filling of the tank, with its entire exchange surface immersed in the liquid to be treated.This exchanger is exclusively reserved for heat treatment in the liquid phase (must or wine).

Kreyer internal heat exchanger

Ancillary systems

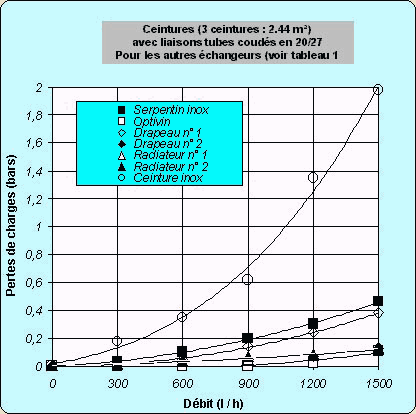

Tared safety valves must sometimes be installed on the exchanger circuit, when it cannot withstand the pressures that may be reached in the hydraulic network (in the case of belts or double envelopes). As a general rule, it is essential for the design office or installer to know the test and operating pressures (as a function of flow rate) of these exchangers. As an example, the graph in Figure 1 shows the pressure losses measured as a function of flow rate on a sample of exchangers.The maximum recommended test pressure for coils, drains or radiators is 10 bar (operating pressure of 2 to 3 bar). The maximum recommended test pressure for belts and double jackets is 4 bar (operating pressure of 2 to 3 bar).

The installation of exchangers above the hydraulic distribution and evacuation network means that automatic air vents must be installed at the top of the exchanger circuit. Some exchangers are fitted with vents at the bottom which allow the circuit to be drained completely.

Pressure losses of exchangers as a function of flow rate

How to use

White winemaking heat exchangers

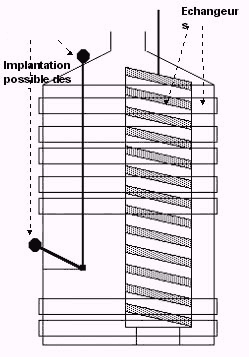

The heat exchangers in the cooling or fermentation vats must be positioned so as to operate from the top of the vat, in order to cool the must evenly. The temperature measured by the probe should be approximately 1/3 of the tank from the bottom and about halfway between the centre and the wall of the tank or, in the case of internal exchangers, between the exchanger and the wall. In the case of internal exchangers, these must be free of connections inside the tanks because of the risk of leaks (welds only, possibly conical connections with installer's guarantee).The exchangers must be removable (sheathing system with cable gland recommended) but rigidly fixed at the top and bottom during operations. Fixed installation during vinification is strongly recommended.

Temperature probes must be removable (sheath system recommended) but rigidly fixed to the top or side of the tank during operations.

Diagram of a white winemaking vat

Red winemaking heat exchangers

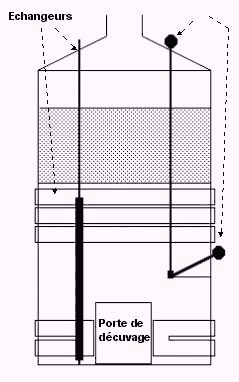

The heat exchangers in red vinification vats should be positioned so that they only work in the juice, below the marc cap and rather in the lower part of the vat (malolactic fermentation), i.e. for Bordeaux vinification, in the lower half of the vat, above the lees. The temperature probe should be positioned about 1/3 of the way down the vat (adjustable height if possible) and about halfway between the heat exchanger and the vat wall.The exchanger (in the case of a flag or radiator) should be positioned sideways, as seen from the door at the bottom of the tank, so as to interfere as little as possible with decanting (off-centre position recommended).

The heat exchangers must be removable (sheath system recommended) but rigidly fixed at the top and bottom during operations. Fixed installation is strongly recommended.

Temperature probes must also be removable but rigidly fixed to the top or side of the tank during operation.

The heat exchangers must not have any connections inside the tanks because of the risk of leaks (welds only, conical connections if necessary with installer's guarantee).

Diagram of a red winemaking vat

Choice of equipment

The surface area of a heat exchanger is always determined at the optimised flow rate, i.e. at the flow rate required to obtain optimum performance from the exchanger.

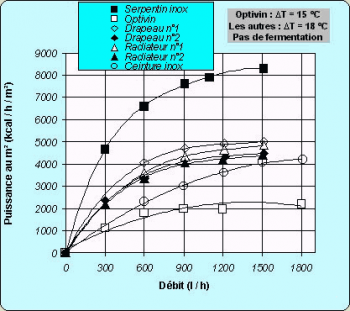

The table and figure below can be used to estimate these flow rates for a sample heat exchanger

ΔT: Temperature difference between the water and the must or wine.

Exchanger power as a function of flow rate

| Type of exchanger | Optivin | Stainless steel belt | Flag n°1 | Flag n°2 | Radiator n°1 | Radiator n°2 | Stainless steel coil |

|---|---|---|---|---|---|---|---|

| Surface area (m²) | 1,04 | 3,25 | 1 | 1,31 | 1,2 | 1 | 0,68 |

| Optimised flow rate (L/h) | 1200 | 2000 | 1500 | 1500 | 1500 | 1500 | 1500 |

For this optimised flow rate, determining the power per m² of the exchanger (Q/m²) depends on the type of exchanger used and the temperature difference DTlog between the must or wine and the temperature of the water circulating in the exchanger.

This relationship can be obtained either using the degree 2 polynomials in the table below or using the graphs in the figure opposite.

This relationship can be obtained either using the degree 2 polynomials in the table below or using the graphs in the figure opposite.

Heat exchanger capacity as a function of DTLOG

| Q/m² = A * DTlog² + B * DTlog + C | COEFFICIENT A | COEFFICIENT B | COEFFICIENT C |

|---|---|---|---|

| STAINLESS STEEL BELT | 5.0389 | 142.03 | -155.78 |

| STAINLESS STEEL FLAG | 6.8629 | 166.06 | -30.107 |

| STAINLESS STEEL RADIATOR | 6.8629 | 166.06 | -30.107 |

| SERPENTINE STAINLESS STEEL | 13.535 | 323.15 | -207.02 |

OPTIVIN |

-0.493 | 160.08 | -44.491 |

The exchange surface area required for the tank to be equipped depends on the maximum power to be supplied for this tank, determined in the heat balance.

The calculated heat exchange surface area is given by the relationship :

S calculated (m²) = Maximum tank power /Power per m² of exchanger

The heat exchange surface area to be installed is then given by the equation :

Exchange surface area S (m²) = Calculated S (m²) + Fouling coefficient * Calculated S (m²)

* For this type of exchanger, the fouling coefficient is set at 25%

Numerical example:

A 200 hl vinification vat requires a maximum power Q = 5747 frig/h to maintain its fermentation temperature at 18°C (see chapter "Assessment of thermal requirements").

The chilled water entering the exchanger is at a temperature of 6°C and leaving the exchanger at 9°C. The water flow rate is around 2 m3/h.

DT log =( (18-6) + (18-9)) / 2 = 10.5 °C

For a stainless steel coil, the power per m² is :

Q/m² = 13.535 * (10.5²) + 323.15 * 10.5 - 207.02

Q/m² = 4678 frig/h/m²

The calculated heat transfer surface area is: S calculated = Q / (Q/m²) = 5747 / 4678 = 1.23 m²

The exchange surface to be installed is then : S = 1.23 + (1.23 * 0.25) = 1.6 m²

A 200 hl vinification vat requires a maximum power Q = 5747 frig/h to maintain its fermentation temperature at 18°C (see chapter "Assessment of thermal requirements").

The chilled water entering the exchanger is at a temperature of 6°C and leaving the exchanger at 9°C. The water flow rate is around 2 m3/h.

DT log =( (18-6) + (18-9)) / 2 = 10.5 °C

For a stainless steel coil, the power per m² is :

Q/m² = 13.535 * (10.5²) + 323.15 * 10.5 - 207.02

Q/m² = 4678 frig/h/m²

The calculated heat transfer surface area is: S calculated = Q / (Q/m²) = 5747 / 4678 = 1.23 m²

The exchange surface to be installed is then : S = 1.23 + (1.23 * 0.25) = 1.6 m²

In the case of belt or double shell heat exchangers, it is necessary to take account of heat losses to the ambient air from this type of exchanger. This power must be added to the overall heat balance. Figure 4 can be used to estimate these losses.

* Glycol water is used when it is necessary to reach must or wine temperatures below 10°C (cold stabilisation, tartaric stabilisation, etc.).

Numerical example:

A 200 hl vinification tank requires Q = 5747 frig/h to maintain the fermentation temperature at 18°C.

The chilled water entering the belt is at a temperature of 6°C and leaving at 9°C.

Q/m² = 1891 frig/h/m² ( 5.0389 * (10.5²) + 142.03 * 10.5 - 155.78)

Calculated S = Q / (Q/m²) = 5747 / 1891 = 3.04 m²

Exchange surface area to be installed: S = 3 + (3 * 0.25) = 3.75 m²

Heat loss from the belt Q = 3.75 m² * 500 frig/h/m2 = 1875 frig/h (see chart)

A 200 hl vinification tank requires Q = 5747 frig/h to maintain the fermentation temperature at 18°C.

The chilled water entering the belt is at a temperature of 6°C and leaving at 9°C.

Q/m² = 1891 frig/h/m² ( 5.0389 * (10.5²) + 142.03 * 10.5 - 155.78)

Calculated S = Q / (Q/m²) = 5747 / 1891 = 3.04 m²

Exchange surface area to be installed: S = 3 + (3 * 0.25) = 3.75 m²

Heat loss from the belt Q = 3.75 m² * 500 frig/h/m2 = 1875 frig/h (see chart)

* Glycol water is used when it is necessary to reach must or wine temperatures below 10°C (cold stabilisation, tartaric stabilisation, etc.).

External heat exchanger

The external heat exchanger, combined with the production of hot water, steam, chilled water or glycol, has a very wide range of applications for all operations requiring significant thermal power:

- Dynamic cooling of musts at low temperature

- Dynamic cooling of the harvest

- Thermovinification

- Final hot maceration at high temperature

- Tartaric stabilisation of wines for large units

External heat exchanger

The type of heat exchanger and the characteristics of the heat transfer fluids must be chosen according to the temperatures to be reached and the type of product to be treated.

Technical presentation

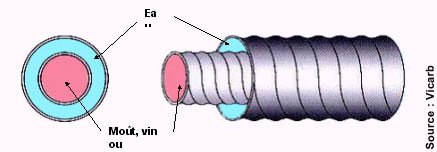

External heat exchangers provide rapid heating or cooling of must, grapes or wine circulated by a pump. These exchangers are supplied with chilled or glycoled water, hot water or steam. We will not deal here with heat exchangers integrated into cooling units or wine cooler-heaters, which operate on the same principle (water is replaced by the refrigerant).Multi-tube exchanger

Multi-tube exchanger: Source Vicard

Coaxial exchanger

Coaxial exchanger : Source Vicard

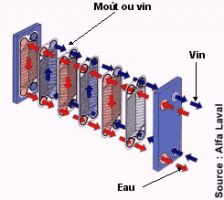

Plate heat exchangers

Plate heat exchangers are mainly used for wine during the tartaric stabilisation phase, pasteurisation or for temperature-controlled bottling.

Exchanger

Plate heat exchanger

Scraped surface exchanger

Special case of scraped surface exchangers

This type of exchanger is mainly used for heat treatment of viscous products (such as grapes). The rotating scraper allows the product to be stirred, which homogenises the temperature, and the heat exchanger surface to be cleaned continuously. The downside of this improvement in thermal efficiency is that the grapes or must are more heavily crushed, and cleaning is more difficult.Special case of trickling water heat exchangers

Trickling water heat exchangers operate on the principle of water evaporation from tubes through which the product to be cooled circulates. Due to high water consumption and the need to install a cooling tower to recycle the water, this type of exchanger is now only used for pre-cooling thermovinified grapes or for cooling vapours in flash-detente processes (Iméca company).

Water trickling exchanger

Main components

The tubes or plates used must be made of stainless steel.Some manufacturers of coaxial or multi-tube exchangers use corrugated tubes to improve the exchange coefficient by making the product rotate in the tube. The diameters or passage widths used for the wine industry vary from 30-40 mm for loaded musts to 70-140 mm for fresh grapes

The external heat exchangers must be installed with the control and safety features appropriate to any hydraulic network.

The wine, grape harvest or must circuit must have thermometers or temperature probes at the exchanger inlet and outlet. The exchanger is fitted with a drain at the low point on the water and wine circuits.

The water circuit must also be fitted with these elements.

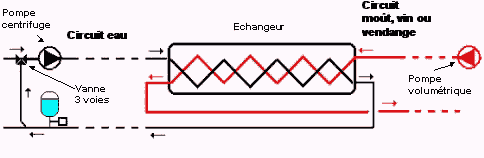

Installation

To obtain the desired temperatures at the outlet of an external exchanger, it is possible to control both the temperature of the water using a three-way valve and the flow rate of the must, wine or grapes using a volumetric pump of the piston or "pigtail" type fitted with a flow variator.

External heat exchanger installation diagram

The installation and initial start-up of an external heat exchanger can only be carried out by a specialist company, which must provide the user with all the recommendations for restarting, using and stopping the exchanger in the form of a user manual. However, a wintering and restarting contract can be signed with the company.

Choice of equipment

This type of heat exchanger is required for heat treatment of large volumes of must or grapes and/or when a given temperature needs to be reached very quickly and evenly.The operations requiring this type of equipment are heating or cooling of grapes or must with large temperature variations (thermovinification, initial cold maceration, cooling of white must, final hot maceration at high temperature, etc.).

The heat output required for the operation to be carried out (see chapter on "Assessing heat requirements") will determine the heat exchanger surface area to be installed. The power of an external heat exchanger is given by the following formula:

Q = K * S * ΔTlog

whereQ: Power calculated during the heat balance (W or frig/h or kcal/h)

K: Overall exchanger fouling coefficient (W/m²/°C or Kcal/h/m²/°C)

S: Exchange surface area (m²)

ΔTlog: logarithmic temperature difference between the inlet and outlet of a heat exchanger (°C)

ΔTlog ≡ (ΔTa + ΔTb) / 2 (approximate formula)

or ΔTa = Teau(inlet) - Tvin(outlet)

and ΔTb = Teau(outlet) - Tvin(inlet)

or ΔTa = Teau(inlet) - Tvin(outlet)

and ΔTb = Teau(outlet) - Tvin(inlet)

Example of cooling white musts (see chapter on "Assessment of thermal requirements") using a multitube heat exchanger:

Q calculated = 17890 frig/h

- Teau(inlet) = 7°C - Tmoût(outlet) = 15°C

- Teau(outlet) = 13 °C - Tmoût(inlet) = 27 °C

→ ΔTlog = - 11 °C

K dirty heat exchanger = 400 kcal/h/m²/°C = -400 frig/h/m²/°C

S = 17890 / -400 / -11 = 4.06 m²

Q calculated = 17890 frig/h

- Teau(inlet) = 7°C - Tmoût(outlet) = 15°C

- Teau(outlet) = 13 °C - Tmoût(inlet) = 27 °C

→ ΔTlog = - 11 °C

K dirty heat exchanger = 400 kcal/h/m²/°C = -400 frig/h/m²/°C

S = 17890 / -400 / -11 = 4.06 m²

The external dynamic exchangers currently on the market are listed in the table below:

| Type | Performance | Advantages | Disadvantages |

|---|---|---|---|

| MULTI-TUBE | Average to good | Treatment of heavy musts Easy to build |

Long floor length |

| COAXIAL | Good | Treatment of heavy musts Good cleanability |

Overall dimensions |

| WITH PLATES | Excellent | High performance Space-saving |

Not suitable for musts that are too full (too small a passage cross-section) |

| COAXIAL LARGE SECTION (Harvest processing) |

Low | Homogeneous heat treatment of the entire harvest | Large exchange surface area and footprint |

| RACELLED SURFACE (Grape harvest treatment) |

Low to medium |

Homogeneous heat treatment of the entire harvest with stirring by scraper |

The specifications for an external heat exchanger must be clearly set out in a specification sheet with the following information to enable the design office and installer to set up the unit correctly.