Harvest pump

Harvest pumps are essential in the winemaking process to transport destemmed or fermented grapes to the fermentation tanks or presses. They are used during the harvest period to ensure efficient transfer, minimising damage to the fruit and preserving its quality. There are several types of grape harvest pump, each adapted to specific needs.

The elliptical rotary piston pump, less common today, is used for vatting and de-vatting, positioned directly under a grape harvest skip or sorting table. The helical rotor pump, or "pigtail", is ideal for transferring over long distances or high elevations, thanks to its regular, non-pulsating flow. The peristaltic pump, which is self-priming and reversible, works well dry and is suitable for the same applications, although it takes up more space. Finally, the lobe pump, with its independent rotors, prevents the formation of sludge and ensures a continuous, gentle flow of grapes. These different pumps are chosen according to the specific needs of the winery, the type of grapes and the winemaking process used.

The elliptical rotary piston pump, less common today, is used for vatting and de-vatting, positioned directly under a grape harvest skip or sorting table. The helical rotor pump, or "pigtail", is ideal for transferring over long distances or high elevations, thanks to its regular, non-pulsating flow. The peristaltic pump, which is self-priming and reversible, works well dry and is suitable for the same applications, although it takes up more space. Finally, the lobe pump, with its independent rotors, prevents the formation of sludge and ensures a continuous, gentle flow of grapes. These different pumps are chosen according to the specific needs of the winery, the type of grapes and the winemaking process used.

Elliptical rotary piston grape harvest pump

Also known as an ogive pump or elliptical rotor pump, the elliptical rotary piston pump is a single-shaft volumetric rotary pump.It is less commonly used today, as it is considered to be of lower quality and more cumbersome than a pump with a helical or peristaltic rotor.

Suitable for vatting whole, de-stemmed grapes, it is positioned directly at the outlet of a grape skip, sorting table or under a crusher. It can also be used to remove fermented grapes to feed a press.

An electric motor drives the elliptical rotary piston rotating on its central axis inside a cylindrical pump body. A non-return valve permanently follows the rotary piston by means of a spring. The screw is fed either in line with the rotor or at right angles to it.

Elliptical rotary piston pump

Operating diagram of an elliptical rotary piston pump

- Note : Planetary rotor pump

Planetary rotor pump

Helical rotor grape pump

The helical rotor pump, also known as a screw or "pigtail" pump, is a single-shaft rotary positive-displacement pump with reversible operation and a regular, non-pulsating flow rate, suitable for transferring materials over long distances or with a high head. It is not recommended for dry use. For this reason, it can be fitted with a level sensor and variable speed drive to operate at maximum efficiency. However, this type of pump is difficult and expensive to maintain.The helical rotor pump is made up of two helical gears, with the rotor rotating inside the stator. The eccentric rotating movement of the rotor allows the pumped product to be conveyed. The size of the rotor/stator for the helical rotor grape pump is larger, however, in order to transfer and store whole destemmed grapes and quasi-solid matter.

These pumps can reach discharge pressures of 20 to 60 bar. Maximum flow rate is 500 m3/h. Positioned directly at the outlet of a grape-hopper, sorting table or under a crusher, they are often used to feed vats or presses.

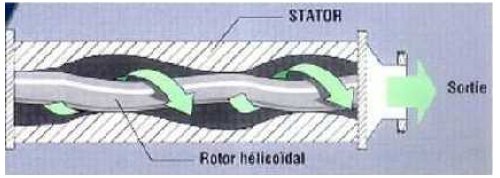

Helical rotor pump

Operating diagram of a helical rotor pump

Peristaltic grape harvest pump

The peristaltic grape harvest pump is a single-shaft, self-priming, reversible volumetric rotary pump that can run dry at very low speed. It is suitable for transferring grapes over long distances or with a high head. However, its pulsed flow rate means it cannot be used to feed a filter, for example. This pump takes up more space and is heavier to handle.It works on the same principle as a wine pump, but the inlet and outlet diameters and the size of the pump are larger for use on whole, destemmed grapes. It can be positioned directly at the outlet of a grape skip, sorting table or under a crusher. The pumping effect is obtained by the compression of an elastomer tube by rollers fixed to the rotor. As the rollers move, they carry the grapes or marc to the discharge.

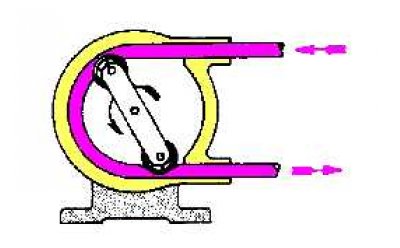

Peristaltic pump

Operating diagram of a peristaltic pump

Lobe grape pump

The lobe grape pump is a rotary positive-displacement pump with two shafts.

The fluid is moved between the rotors and the pump body. The rotors are driven by an independent mechanism.

The space available between the lobes enables the harvest to be transported without the formation of sludge. Impellers are made up of one, two, three or four lobes.

The liquid flow is continuous and there is no agitation.

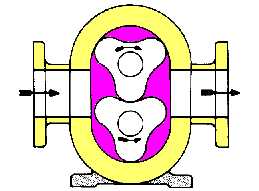

Diagram of how a lobe pump works