Wine pump

Wine pumps play a crucial role in the winemaking process, being used to transfer wine at various stages of production, including racking, filtration and bottling. They enable the wine to be transferred efficiently and gently, minimising exposure to oxygen and thus preserving the quality of the final product.

There are several types of wine pump adapted to different needs. Centrifugal pumps are commonly used for their ability to move large quantities of liquid quickly, although their action can result in some aeration of the wine. Piston pumps, offering a steady flow and gentle handling of the wine, are preferred for operations requiring low oxidation. Peristaltic pumps, self-priming and capable of running dry, are ideal for precise and delicate transfers, often used for racking and bottling. Lobe pumps, with their continuous, non-pulsating flow, are effective for transfers where stability and smoothness are essential. Finally, diaphragm pumps, which use mechanical action to move the wine, are used for specific operations requiring minimal handling of the product.

There are several types of wine pump adapted to different needs. Centrifugal pumps are commonly used for their ability to move large quantities of liquid quickly, although their action can result in some aeration of the wine. Piston pumps, offering a steady flow and gentle handling of the wine, are preferred for operations requiring low oxidation. Peristaltic pumps, self-priming and capable of running dry, are ideal for precise and delicate transfers, often used for racking and bottling. Lobe pumps, with their continuous, non-pulsating flow, are effective for transfers where stability and smoothness are essential. Finally, diaphragm pumps, which use mechanical action to move the wine, are used for specific operations requiring minimal handling of the product.

Reciprocating positive displacement pumps

Reciprocating piston wine pump

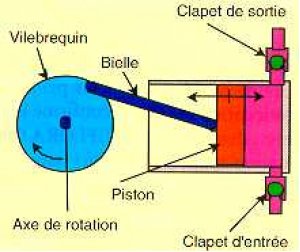

The reciprocating piston wine pump is an alternative volumetric pump with the advantage of being self-priming, reversible and able to run dry. Its flow rate is relatively low, but it offers good efficiency of around 90%. It is robust, easy to use and particularly suitable for transferring water over long distances or with a high head.The reciprocating piston pump uses the variations in volume caused by the movement of a piston in a cylinder. These movements, alternately in one direction or the other, produce suction and delivery phases. When the piston moves in one direction, the liquid is compressed: the inlet valve closes and the outlet valve opens. The opposite occurs when liquid is drawn into the pump.

Reciprocating piston pump

Diagram of a reciprocating piston pump

However, pulsed flow is not suitable for feeding certain filters. In fact, there are significant pulsations at the discharge: this can be remedied by using anti-hammer pots (or air bells). These devices dissolve a lot of oxygen in the wine.

The reciprocating piston wine pump is unsuitable for solid and corrosive materials (kieselguhr, perlites): the pump only works well if there is a perfect seal between the cylinder and the piston.

Lastly, the bronze pump body of older models can cause leaks when the wine passes through, so stainless steel pump bodies are preferable.

Diaphragm wine pump

The diaphragm wine pump is an alternative volumetric, self-priming, reversible pump with a pulsed flow rate.

It operates in a similar way to a reciprocating piston pump. A diaphragm is attached to the piston and moves back and forth.

The advantage of diaphragm pumps is that they can work with corrosive, abrasive or acidic products.

Diaphragm pump

Single-shaft rotary positive-displacement pumps

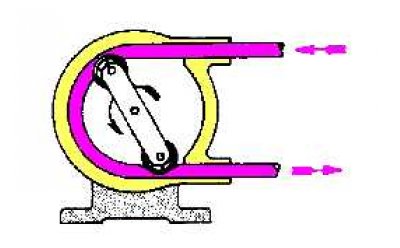

Rotary vane wine pump

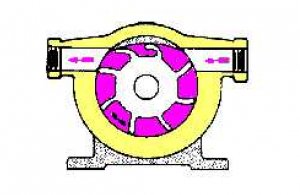

The flexible vane wine pump is a single-shaft, reversible, rotary positive-displacement pump. It is easy to use, easy to handle and takes up very little space. It is easy to dismantle and clean. These pumps deliver regular flow rates of up to 100 m3/h and discharge pressures of 4 to 8 bar.A fixed cylindrical casing communicates with the suction and discharge ports. The movement of the rotor continuously rotates the different volumes between the cylinder and the flexible vanes, sucking in the fluid on one side and discharging it on the other. This type of pump can cause internal leaks and wine stirring.

Flexible vane pump

Diagram of a vane pump

The disadvantage of vane pumps is that they are not suitable for high heads or viscous fluids. They do not run dry.

Note the sometimes rapid wear of the casing and vanes due to friction when the pump is in use.

Eccentric rotor wine pump

The eccentric rotor pump is a single-shaft rotary positive-displacement pump with a regular, non-pulsating flow rate. It can run dry and at fairly low speedThe cylindrical rotor mounted on an eccentric rotates by resting on the inner wall of the stator, moving the fluid from suction to discharge.

Eccentric rotor pump

Eccentric rotor pump diagram

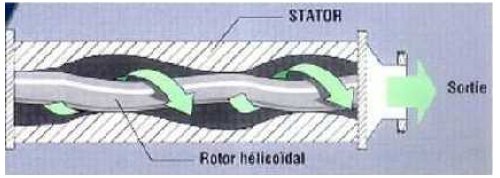

Helical rotor wine pump

The helical rotor pump, also known as a screw or "pigtail" pump, is a single-shaft rotary positive-displacement pump with reversible operation and a regular, non-pulsating flow rate, suitable for transferring wine over long distances or with a high head. It is not recommended for dry use. For this reason, it can be fitted with a level sensor and variable speed drive to operate at maximum efficiency. However, this type of pump is difficult and costly to maintain.The helical rotor pump consists of two helical gears, with the rotor rotating inside the stator. The eccentric rotating movement of the rotor allows the pumped product to be conveyed.

The size of the rotor/stator for the helical rotor wine pump is narrower than for grape harvest pumps, as the pump only transports products in the liquid phase.

Helical rotor pump

Operating diagram of a helical rotor pump

These pumps can reach discharge pressures of 20 to 60 bar. Maximum flow rate is 500 m3/h. Positioned directly at the outlet of a grape harvest skip, sorting table or under a crusher, they are often used to feed vats or presses.

Peristaltic wine pump

The peristaltic wine pump is a single-shaft, self-priming, reversible volumetric rotary pump that can run dry at a very low speed. It is suitable for transferring grapes over long distances or with a high head. However, its pulsed flow rate means it cannot be used to feed a filter, for example. This pump takes up more space and is heavier to handleThe pumping effect is obtained by compressing an elastomer tube through rollers fixed to the rotor. As the rollers move, they carry the grapes or marc to the discharge.

Peristaltic pump

Operating diagram of a peristaltic pump

Rotary positive displacement pumps with two shafts

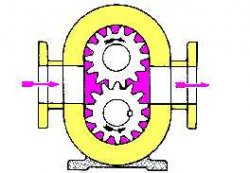

Gear pump

The gear pump is a two-shaft rotary positive-displacement pump, also known as a double-rotor pump. It delivers a regular flow and can be reversible.It consists of two gears rotating inside the pump casing. The principle consists of drawing the liquid into the space between two consecutive gear teeth and passing it to the discharge section.

These pumps can achieve discharge pressures of between 5 and 30 bar. Flow rates can reach 300 m3/h. Maximum head is 50 to 200 m w.g.

Caution: gear pumps do not allow solid particles or abrasive products to pass through them, as this could lead to mechanical wear of the pinions, reduce the seal between the pump casing and the teeth, or even destroy the pumping system.

These pumps can achieve discharge pressures of between 5 and 30 bar. Flow rates can reach 300 m3/h. Maximum head is 50 to 200 m w.g.

Caution: gear pumps do not allow solid particles or abrasive products to pass through them, as this could lead to mechanical wear of the pinions, reduce the seal between the pump casing and the teeth, or even destroy the pumping system.

Diagram of a gear pump

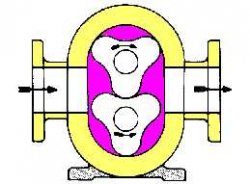

Lobe wine pump

The lobe wine pump is a volumetric rotary pump with two shafts. The pump is reversible, with a low rotation speed and a very regular, non-pulsating flow rate. This makes it a respectful and versatile pump. The liquid flow is continuous and there is no mixing.The fluid is moved between the rotor and the pump casing. The rotors are driven by an independent mechanism. Impellers are made up of one, two, three or four lobes. Lobe pumps are easy to dismantle for cleaning and maintenance.

Operating diagram of a lobe pump

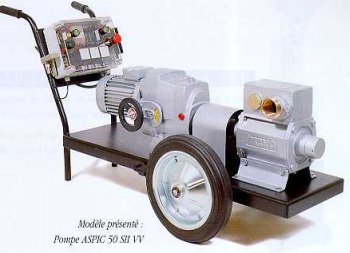

Rotary piston wine pump

New-generation volumetric pump, self-priming, reversible, can run dry, is easy to dismantle and clean, and has a slightly pulsating flow.Its main advantages are that it self-regulates according to back pressure to operate at maximum efficiency and limits contact with the air.

Rotary piston pump

Rotodynamic pumps

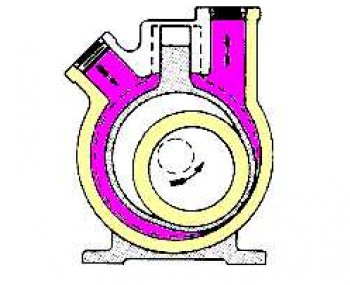

Centrifugal wine pump

The main advantage of the centrifugal pump is its low maintenance cost. Centrifugal pumps are compact and lightweight, making them easy to handle, dismantle and clean.

Centrifugal pumps cannot prime themselves, and can "cavitate": the air contained in the pump must first be expelled. Centrifugal pumps are not effective for wines with a high viscosity.

To avoid defuelling the pump each time it is restarted, it may be worth using a non-return valve at the foot of the suction pipe.

Finally, operating at high rotation speeds causes the wine to stir and emulsify considerably. We strongly advise against using them on wines that are still maturing.

Centrifugal pumps cannot prime themselves, and can "cavitate": the air contained in the pump must first be expelled. Centrifugal pumps are not effective for wines with a high viscosity.

To avoid defuelling the pump each time it is restarted, it may be worth using a non-return valve at the foot of the suction pipe.

Finally, operating at high rotation speeds causes the wine to stir and emulsify considerably. We strongly advise against using them on wines that are still maturing.

Centrifugal pump

Centrifugal pumpSide channel wine pump

Side channel pump

The side-channel wine pump is a self-priming rotodynamic pump. It is easy to use and versatile, with a high rotation speed. The impeller is finned and ringed.

The side channel is located in the casing and cover. The side channel principle ensures that the product is transferred without emulsion, reducing the amount of mixing. They are therefore better suited to wine transfers than centrifugal pumps.

The side channel is located in the casing and cover. The side channel principle ensures that the product is transferred without emulsion, reducing the amount of mixing. They are therefore better suited to wine transfers than centrifugal pumps.