Punch-down tool

In oenology, a pinch-down tool is an essential tool for pressing the cap of marc into the juice during the vinification of red grapes, promoting the extraction of phenolic compounds. This equipment also allows the cap of marc to be immersed and crumbled, improving the release of polyphenolic compounds. This equipment also allows the cap of marc to be immersed and crumbled, improving the release of polyphenolic compounds.

There are manual punch-downs, consisting of a handle with inclined teeth or a pressing cup, and mechanical punch-downs, often mounted on rails with pneumatic cylinders to automate the process. Mechanical piggers can also be integrated into specific tanks or in the form of turbines fitted with a propeller, and can be mobile to process several tanks.

There are manual punch-downs, consisting of a handle with inclined teeth or a pressing cup, and mechanical punch-downs, often mounted on rails with pneumatic cylinders to automate the process. Mechanical piggers can also be integrated into specific tanks or in the form of turbines fitted with a propeller, and can be mobile to process several tanks.

Manual punch-down

Manual punch-down

During vinification of red grapes or during maceration, this equipment is used to manually push the cap of marc into the juice, crumbling it with the force of the arms.

It is a simple tool consisting of a removable handle, a pressing cup and inclined teeth for crumbling the marc.

Mobile mechanical punch-down

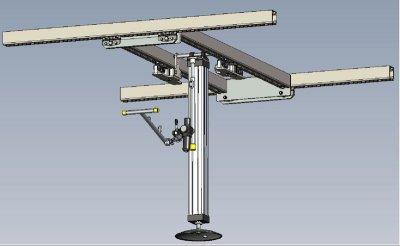

Punching down can also be carried out using mobile punch-down robots. This mobile equipment runs on rails. It allows the winemaker to use the punch-down on several vats installed in lines.It consists of a mobile chassis on rails or a hoist, cylinders (usually pneumatic) fitted with tools at the end, and a lever for adjusting the intensity of pressing.

Mechanical punch-downs on rails or wheels

Integrated punching tank

Integrated punching cylinder

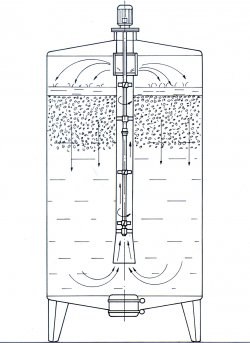

Tank with integrated punching down system

Several manufacturers offer integrated punching down tanks.

The punching of the cap is carried out by tools of varying shapes, driven by cylinders, usually pneumatic (1 to 4 depending on capacity and manufacturer).

The vats are small (100 to 400 hl), made of stainless steel and sometimes wood.

Turbine punch down

These devices are a more economical alternative to the purchase of special fermentation tanks.

They fit into most vats with a central chimney and are high enough to be inserted through the chimney. However, they can be difficult to handle , unless the winery is equipped with an overhead crane to move the equipment from vat to vat (for vats with sufficient height).

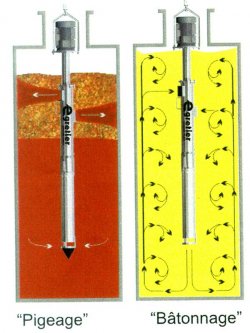

Using the principle of an axial propeller pump in a stainless steel column, this equipment can also be used for pumping over.

Turbopigeur

One manufacturer offers this equipment for pumping over and punching down the cap by immersion. The Turbopigeur consists of a turbine (accelerator) and an acceleration chamber where the liquid rises in a helical path. This mobile device is designed for pumping at very high flow rates, causing the cap of marc to sink.The Pigeur Intégral

The Pigeur Intégral uses the power of a motorised propeller to inject the must directly into the cap of marc to break it up. It can also be used as a stirrer during maturation.

Principle of turbine punching down and pumping over

Turbine pigeage