Extraction tank

The special vinification vats are designed to optimise extraction and fermentation. Horizontal rotating vats, with a helicoidal plate, allow the marc to be stirred efficiently, speeding up fermentation. Tanks with an internal helix and parallelepipedic tanks with rakes use internal mechanisms to mix the marc and facilitate its removal. Delestage vats dry the marc before reinjecting it into the must to improve extraction of the compounds. Tanks with submerged tops keep the marc pressed into the juice for long vatting periods. Finally, automatic fermentation vats and those using carbon dioxide automate the process for better control.

Special vinification vats

Horizontal rotating vats

Several manufacturers offer horizontal cylindrical tanks mounted on rollers. Inside the VinimaticTM vat, a sheet of metal is continuously welded into a helical profile. The rotation of the vat ensures that the grapes are stirred and the pomace is gradually drawn along the spiral after the door has been opened. These vats have been the subject of numerous experiments.Homogenisation during fermentation generally increases the speed of fermentation and the extraction of colouring matter.

Each cycle (number and frequency of rotations) must be carefully planned to limit the production of lees.

Each cycle (number and frequency of rotations) must be carefully planned to limit the production of lees.

Horizontal rotating vats

Horizontal tanks with an internal propeller

Their configuration is similar to the previous ones. Homogenisation is no longer achieved by rotation of the vat, but by rotation of the internal spirals.Parallelepiped tanks with rakes

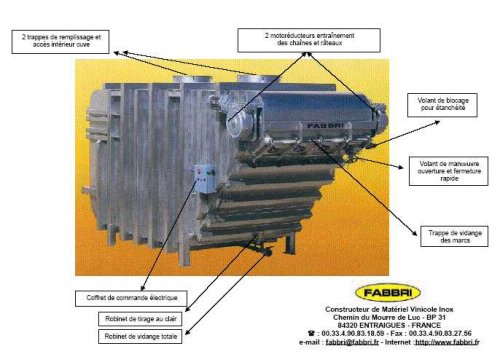

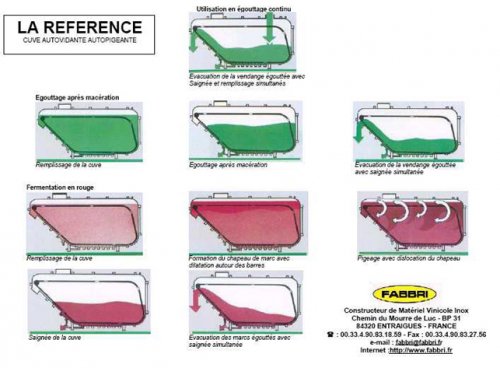

These tanks are made up of a parallelepiped-shaped stainless steel container, with one of the front faces inclined. Horizontal bars called rakes, driven by chains, ensure that the marc is stirred and drained during devatting. A large draining grid is used to dry the marc.Operating principle

It is a static, parallelepipedal tank made entirely of stainless steel.Drainage grids cover most of the bottom. The sloping front has other grids and a full-width door at the top.

Stainless steel chains run along the inside walls, powered by two geared motors that drive crossbars.

The bars pass flush with the bottom, unclogging the grids, rise up the inclined plane at the front and then continue backwards through the upper part of the tank. This return will be made in the cap of marc in red vinification and will allow the immersion of this cap.

This vat also has doors, draining taps and the traditional equipment of a storage vat.

These tanks, which are widely available, generally enable faster fermentation, with gains in polyphenol extraction. They are multi-purpose (draining, fermentation, carbonic maceration and possibly storage). The number and intensity of stirring must be limited. Cleaning the draining rack and the part underneath remains a delicate task.

Special raked vat

Self-draining tank

DELESTAGE TANK

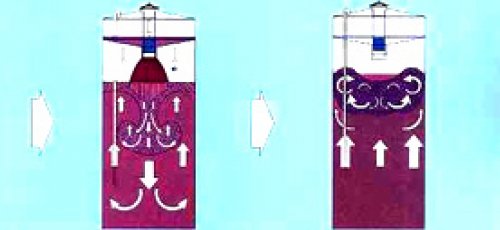

Delestage is an increasingly popular technique. It consists of drying the marc for a few hours and then pumping the must at a high flow rate through the top of the vat to ensure that the cap is dislocated and washed away.

This requires a large volume of vat room and the use of very high flow pumps. The flow capacity of the vat is sometimes a limiting factor.

Bars (or chains) built into these tanks help to break up the cap of marc as the must runs off. The system must be designed in such a way as not to twist the shell of the vat when the force is exerted on the marc cap (reinforcement bars). It must also not hinder the reformation of the marc cap during refilling.

This requires a large volume of vat room and the use of very high flow pumps. The flow capacity of the vat is sometimes a limiting factor.

Bars (or chains) built into these tanks help to break up the cap of marc as the must runs off. The system must be designed in such a way as not to twist the shell of the vat when the force is exerted on the marc cap (reinforcement bars). It must also not hinder the reformation of the marc cap during refilling.

Bars of a deballasting tank

Delestage principle

To overcome this disadvantage, some manufacturers offer cylindrical tanks into which a second perforated tank has been inserted along the same axis. The presence of this perforated vat would also cause the cap to sink during maceration. Tanks with two compartments, connected by fixed or mobile piping, are well suited to this technique.

The example opposite illustrates an automated delestage vat room with a must reception tank and a heat exchanger to heat or cool the juice on its return to the maceration tank.

The example opposite illustrates an automated delestage vat room with a must reception tank and a heat exchanger to heat or cool the juice on its return to the maceration tank.

Tank with immersed cap

Some reinforced concrete or stainless steel vats are built and equipped to hold stainless steel or wooden bars. These keep the marc submerged in the juice.This configuration is useful for long vatting periods, but the reliability of the process is closely linked to the quality of the design.

Diagram of the use of a vat with an immersed cap

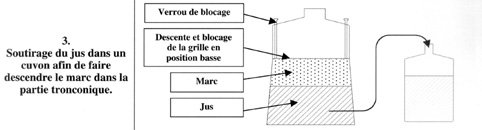

- vatting

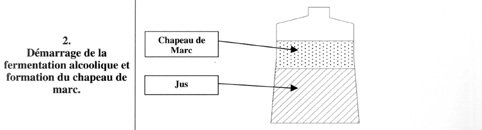

- start of fermentation and formation of the cap

- racking and lowering of the grid and cap

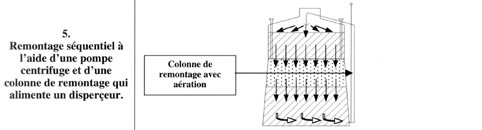

- reassembly and immersion of the cap thanks to the grid

Automatic fermentation tanks

Automatic fermentation tanks consist of a high-capacity storage vat at the top, which allows juice to be released rapidly at a high flow rate onto the cap of marc in the main tank , breaking it up and "leaching" it.Experiments have demonstrated the benefits of high-speed leaching for extracting polyphenols. These vats can also increase the speed of fermentation and therefore reduce vatting time. However, filling the vats is sometimes problematic. The top and bottom of the vat are also often difficult to clean.

SelectorTM or PluviatankTM tanks

Constructed from stainless steel or reinforced polyester, these consist of a cylindrical main tank with a domed base, topped by a juice reception tank. This represents around one fifth of the tank's total capacity.

The two tanks are connected by a valve.

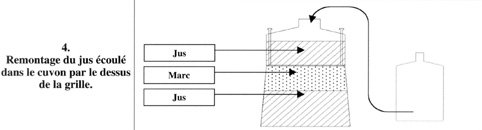

At the bottom, a pump pumps the juice into the vat.

The pump is controlled by a programming unit that adjusts the duration and frequency of pumping.

Some manufacturers also offer 'kits' based on the same principle, which can be adapted to existing vats.

The two tanks are connected by a valve.

At the bottom, a pump pumps the juice into the vat.

The pump is controlled by a programming unit that adjusts the duration and frequency of pumping.

Some manufacturers also offer 'kits' based on the same principle, which can be adapted to existing vats.

Automatic fermentation tanks

Tanks with automatic pump-over or carbon dioxide

The excess pressure of the carbon dioxide produced by fermentation causes the must to rise in the vat. A valve system retains the juice up to a certain volume, beyond which the bottom of the vat opens. Depending on the design, the frequency of pumping over is more or less controllable.

Carbon dioxide pump-over tank

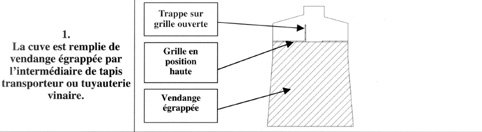

The tank is filled with destemmed grapes either from the bottom or the top.

As the bypass between the two capacities is closed, the air remains trapped outside the diaphragm.

As fermentation progresses, some of the CO2 produced is evacuated through the centre of the diaphragm; the rest remains trapped outside the diaphragm, replacing the fresh air.

When the space is saturated, CO2 is released through the neck of the diaphragm, stirring up the cap of marc.