Vacuum leaf remover

Vacuum leaf removers are viticultural tools that use a vacuum to mechanically suck up and shred vine leaves. They work by creating a suction which directs the leaves towards a cutting bar where they are shredded. There are three main systems:

- with a helical fan or straight blades,

- with rollers and a cutting bar,

- with a turbine.

These systems allow precise and efficient leaf removal, reducing the risk of injury to grapes and facilitating foliage management.

- with a helical fan or straight blades,

- with rollers and a cutting bar,

- with a turbine.

These systems allow precise and efficient leaf removal, reducing the risk of injury to grapes and facilitating foliage management.

Principle of suction leaf removal

Vacuum leaf removal

The leaves are sucked up and then mechanically shredded. Vacuum leaf removers create a vacuum which carries the removed leaves to a cutting unit where they are shredded, like a traditional cutter bar (see photo).

Three suction systems are currently available.

Three suction systems are currently available.

- helical fan or straight blade system

- roller and cutter bar system

- turbine system

Helical fan or straight blade system

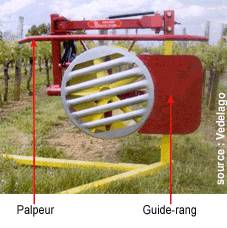

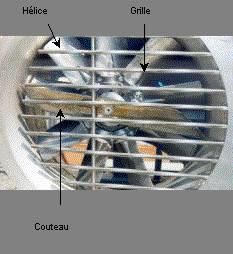

The remover head consists of a grid, a propeller, possibly a knife and a feeler. Suction is produced by the rotation of thepropeller or blades. The drive may or may not be variable speed. The safety grid protects the propeller or blades and prevents contact with the bunches. The position of the grille can be fixed or rotated or slid sideways. Depending on the manufacturer, the leaves are cut by the propeller or by a knife with 2 or 4 blades mounted on the propeller. The distance between the knife and the screen is adjustable for some manufacturers.The grid is preceded by a flat profiled part, called the row guide, over which the leaves slide before being introduced into the grid.

The leaf-stripping head can be fitted with a feeler (sometimes called a feeler) against which the vegetation rests. The distance between the feeler and the grid is adjustable, allowing the grid to be moved further or further away from the vegetation.

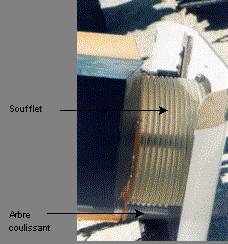

For one of the models on offer, the grid is supported by two sliding shafts, enabling the pressure on the vegetation and therefore the vigour of the leaf removal to be modulated. A bellows connects the grille to the fan.

The knife, placed behind the grille, is not attached to the propeller.

Only one manufacturer offers a leaf-stripping head with two suction units, allowing the working height to be modified.

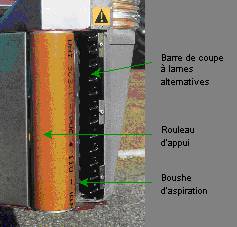

Roller and cutter bar system

The equipment consists of a preparation device: a cutting bar, the purpose of which is to remove any shoots protruding from the vegetation.The leaf-stripping system consists of two reversed-rotation rubber rollers that pull the leaves and remove most of the petioles. The rollers rotate at around 450 rpm.

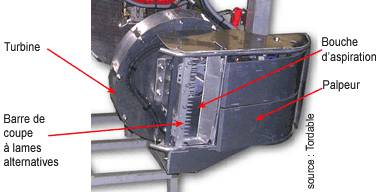

Turbine system

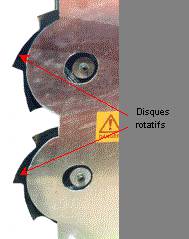

The turbine (or centrifugal fan) creates a vacuum inside the intake opening. The turbine is either mounted on the remover head or placed outside it.A cutting bar with alternating blades or rotating discs shreds the leaves. The vegetation is supported on a support roller or on feelers.