Nozzles and discs

Spray nozzles for viticulture come in several types, including turbulence nozzles, slot nozzles and discs for pneumatic sprayers. Turbulence nozzles create fine, penetrating drops, but are sensitive to drift. Slot nozzles produce a flat spray and are commonly used for weed control. Air injection nozzles, including turbulence and slot variants, produce larger droplets, reducing drift and providing better coverage. Calibrated discs control the flow of the spray and are essential for uniform spraying.

Suitable filtration is crucial to prevent nozzle clogging.

Suitable filtration is crucial to prevent nozzle clogging.

General

Spray drops are generally generated using either:

- nozzles for airblast and airblast sprayers.

- diffusers or splitters for pneumatic sprayers.

- rotary fragmentation systems, found on drones in particular.

These drops are obtained by the disintegration of a liquid filament, leading to the production of a distribution of drop sizes.

In spraying systems, the nozzles break up the liquid into droplets of varying sizes to form a jet. The droplets are formed by the liquid stream passing under pressure through a narrow orifice in the tablet or nozzle. The higher the pressure and the smaller the outlet orifice, the finer the droplets. The choice of nozzle therefore depends on the work objective. A minimum pressure, which varies according to the type of nozzle, is required to obtain a properly formed jet.

The choice of nozzle is crucial because the size of the drops influences the rate of coverage of the vegetation and potential drift.

The factors influencing the droplet spectrum are :

- nozzle type

- nozzle size

- pressure

- the properties of the liquid.

Nozzles

Description

The different types of nozzles are :

- Turbulence nozzles

Used in viticulture for fungicide and insecticide applications, the jet formed is conical, solid or hollow. - Slot, brush or flat-jet nozzles

This type of nozzle can be used at low pressures. Mainly used for weed control, they can also be found on some equipment for fungicide or insecticide treatments. - Discs for pneumatic sprayers

These are used to calibrate the flow rate on pneumatic sprayers.

Non-conventional nozzles are :

- Double slot nozzles

This type of nozzle sprays 2 jets with an angle of around 65° between each jet. - Air injection nozzles

Conventional nozzles are distinguished from air-injection nozzles by the presence of holes in their base through which air is sucked and mixed with the spray liquid during spraying (venturi effect). This mechanism produces larger droplets than those obtained at the same pressure with conventional nozzles. As the drops are (much) larger, they are less susceptible to drift. Slot or turbulence nozzles, air injection nozzles (used in a good pressure range) enable more product to be deposited on the vegetation than conventional nozzles. These nozzles make it possible to reconcile good application quality with reduced drift losses. However, their extreme sensitivity to clogging has put many winegrowers off using them for fungicides (they are much more commonly used for herbicides). Air-injection nozzles can be used in all conditions, but should be used in peri-urban areas and near dwellings.

These nozzles are compatible with all sprayers that use nozzles (airblast, airblast). - turbulence and air injection nozzles: air injection nozzles can be used in viticulture because they charge the droplets with air and therefore reduce potential drift, as the jet is conical in shape.

- slot and air injection nozzles: these produce medium to large drops with a flat spray pattern.

Application volume is linked to working pressure, forward speed and working width.

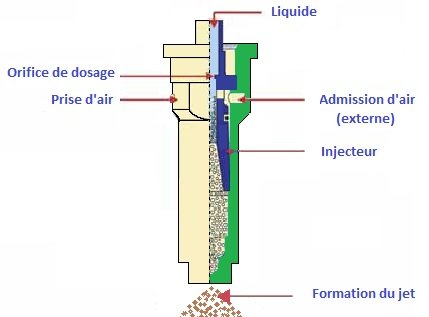

Operating principle of an air injection nozzle

Nozzle size

The size of the nozzle orifice defines its size, which in turn defines the link between the nozzle's pressure and flow rate. The colour of the nozzle defines its size. For ISO nozzles, there are standard tables that define the flow rate according to the colour of the nozzle and the pressure used.Flow = K x S x √P

K : Nozzle coefficient

S: Liquid outlet surface

P: Pressure

Formula for calculating nozzle flow rateK : Nozzle coefficient

S: Liquid outlet surface

P: Pressure

Notes :

- To double the flow rate of a nozzle, the pressure must be multiplied by four, so a poor choice of nozzle cannot be compensated for by adjusting the pressure.

- In practice, nozzle wear is often considered not to affect spraying quality as long as the increase in flow rate is less than 10%.

- Nozzles can be unclogged using compressed air (not easy to do in the field, although small spray cans are now available) or a soft brush. Under no circumstances should you use the blade of a knife or, even less, bring the nozzle to your mouth (product toxicity) and blow into it.

Advice on using air injection nozzles

The proper operation of air-injection nozzles depends on compliance with filtration rules, and the use of suitable filters can limit the clogging of these nozzles.Good filtration helps to maintain constant spray quality. Depending on the type of fluid to be sprayed and its concentration of impurities, it will be important to define the surface area and filtration fineness of the screen. The choice of filter element depends on the fineness of the spray nozzle orifices.

- Filtration fineness is generally expressed in "MESH". It is defined by a colour code (see illustration). The use of air injection nozzles requires filtration before the nozzles of at least 80 mesh!

Colour code for nozzle filters

Turbulence nozzle

Turbulence nozzles

The aim of this nozzle is to create fine droplets with good penetration capacity. The downside is that they are more susceptible to drift and can be a source of diffuse pollution.A drop that is too fine drifts more easily and dries out quickly, so losses can be significant if weather conditions are unfavourable.

The turbulence nozzle consists of two parts: the propeller and the pellet.

The propeller causes turbulence in the liquid (rotary movement) before it is expelled through the pellet to form a hollow conical jet. It is not the jet that is turbulent, but the movement of the liquid inside the nozzle.

Slot, brush or flat jet nozzles

Slot nozzles

This nozzle is used to achieve a spray pattern with better definition than the turbulence nozzle. They are traditionally used on weed control booms. They form a flat, turbulence-free brush spray, the angle of which can vary according to the type of nozzle used (45 to 110°). The droplets obtained are less fine than with a turbulence nozzle, which tends to reduce spray mist.

Double-slit nozzles

Double-slot nozzles

In a way, they consist of two slot nozzles on the same support, with one slot at the front and the other at the rear. So, to obtain the same flow rate, the outlet orifices are smaller and, consequently, the droplets finer.

This nozzle is designed for applications requiring fine droplets for good coverage and penetration of the foliage (e.g. application of fungicides). However, the risk of drift is greater.

This nozzle is designed for applications requiring fine droplets for good coverage and penetration of the foliage (e.g. application of fungicides). However, the risk of drift is greater.

Turbulence and air injection nozzles

Lhe aim of these nozzles is to produce very large droplets of a mixture of spray liquid and air that are not very sensitive to drift. They are identical in construction to conventional turbulence nozzles, but have small holes in the side to allow air to be sucked in as the spray liquid passes through.

Turbulence and injection nozzles

Slot and air injection nozzles

Slot nozzles and air injection

Increasingly used, these nozzles can operate at low pressure. Slot and air injection nozzles produce a spectrum of medium to large droplets with a flat jet (brush) that is not very sensitive to drift.

This gives good application quality.

This gives good application quality.

Tablets

The calibrated pellet breaks up the liquid vein. Formerly a simple perforated metal part, it is now often made of ceramic and can incorporate the propeller. While the pellet is a good starting point for choosing a nozzle, the propeller plays an essential role. For an identical tablet, the choice of propeller can vary the flow rate from 1 to 4. It is therefore essential to ensure that the same propellers are used everywhere to achieve the same flow rate through the nozzles.

Single pellets have their calibre in 1/10th of a mm written on one side. Note that while for stainless steel discs the rule is to position the marked side on the outside so that it is easy to read, the size may be different for certain ceramic discs where the two sides of the disc are asymmetrical. One side has a virtually flat surface, while the other is funnel-shaped, allowing higher flow rates (watch out for inversions).

Single pellets have their calibre in 1/10th of a mm written on one side. Note that while for stainless steel discs the rule is to position the marked side on the outside so that it is easy to read, the size may be different for certain ceramic discs where the two sides of the disc are asymmetrical. One side has a virtually flat surface, while the other is funnel-shaped, allowing higher flow rates (watch out for inversions).

Examples of tablets

AMT pad positioned on the "high flow" side

AMT pad positioned on the "low flow" side

Unlike nozzles, the working pressure (in bar) has no influence on the quality or size of the drops formed. The pellets have a unique role, delivering a quantity of spray liquid in litres per minute.

ALBUZ AMT pellet flow rate table according to orifice used