Inter-row tractor

Vineyard inter-row tractors, designed for work in vineyards, are characterised by their compactness and manoeuvrability, making it easy to navigate between the narrow rows of vines. They are often equipped with powerful yet compact engines, ensuring optimum performance while minimising damage to plants.

The three-point linkage system, which complies with ISO 730 and 8759 standards, makes it easy to use tools specific to viticulture. In addition, their lightweight yet robust design offers excellent stability on the hilly and varied terrain of vineyards.

Finally, these tractors are generally equipped with advanced control and navigation devices for greater precision in vineyard tasks.

The three-point linkage system, which complies with ISO 730 and 8759 standards, makes it easy to use tools specific to viticulture. In addition, their lightweight yet robust design offers excellent stability on the hilly and varied terrain of vineyards.

Finally, these tractors are generally equipped with advanced control and navigation devices for greater precision in vineyard tasks.

The inter-row tractor is classified in category T2 (narrow tractor). Compared with category T1 tractors, the minimum width (track) must be less than 1150 mm and the ground clearance less than or equal to 600 mm. However, when the ratio between the height of the centre of gravity (in relation to the ground) and the minimum track is greater than 9.9, the maximum speed must be limited to 30 km/h.

The qualities required of this type of agricultural tractor depend on the work to be carried out.

Requirements for agricultural tractors

Inter-row tractor

- For pulling work

- For transport and handling work

- For PTO work

Hitch

The tractor-implement linkage is subject to regulations. Standard ISO 730 specifies the dimensions and requirements for three-point rear hitches on wheeled agricultural tractors.

The ISO 8759 standard concerns coupling systems positioned at the front of the tractor.

The coupling system on an agricultural tractor is generally of the "three-point" type. It is made up of a number of components.

There are four categories of hitch in agriculture. In viticulture, the dimensions of hitching systems generally correspond to categories 1 or 2. They are based on the power developed by the tractor at the power take-off (see table below).

The ISO 8759 standard concerns coupling systems positioned at the front of the tractor.

The coupling system on an agricultural tractor is generally of the "three-point" type. It is made up of a number of components.

There are four categories of hitch in agriculture. In viticulture, the dimensions of hitching systems generally correspond to categories 1 or 2. They are based on the power developed by the tractor at the power take-off (see table below).

Lifting arm - Automatic hitch

| Categories | PTO power (Kw) |

|---|---|

| 1N | Up to 35 |

| 1 | Up to 48 |

| 2 | From 30 to 92 |

| 3N / 3 | From 60 to 185 |

| 4N / 4 | From 110 to 350 |

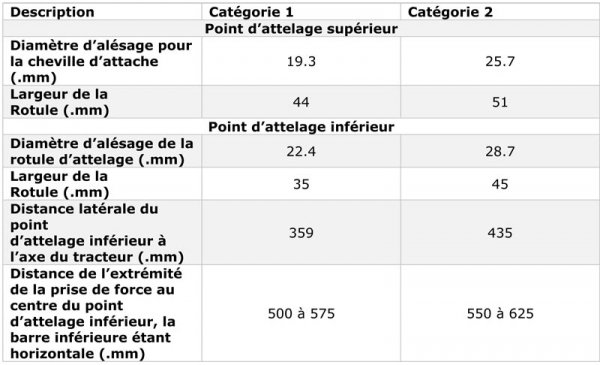

Dimensions for tractor coupling points :

Dimensions of tractor coupling points

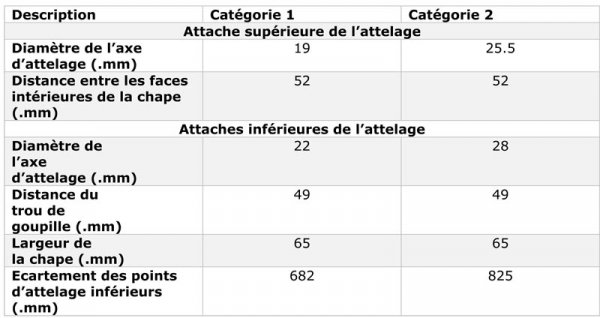

Dimensions for equipment coupling points :

Equipment attachment point dimensions

Some equipment is therefore fitted with two ball size coupling points, allowing equipment based on category 1 dimensions to be connected to couplings based on category 2 dimensions and vice versa.

Ball hitch on serrated disc frame

New-generation tractors are equipped with a complete hitching system to facilitate the development of combined work.

Front 3-point linkage on an inter-row tractor

Rear hitch on an inter-row tractor

Trailer hitch on an inter-row tractor